Table of Contents

ToggleIntroduction

Ordinary LED lights will experience increased light decay, go out and even be damaged in high temperature environments. To ensure lighting safety and stability, it is important to choose professionally designed fixtures with stronger heat resistance.

There are actually only a few types of high temp LED lights used in industrial applications. These are primarily used indoors and outdoors, such as high-bay, floodlights and tri-proof lights. This article will analyze these three main types. You can check out our high temp product series.

1. High Temperature High Bay LED Lights

Simply put, this is a high-temp LED light designed specifically for indoor industrial environments with large spaces, high ambient temperatures and long operating times. It combines the advantages of two mainstream LED lights types, can provide reliable lighting in high-temperature, high-ceiling areas.

- “High-bay” refers to installation heights, typically above 20 feet, and is suitable for locations like stadiums, factories and warehouses lighting. This requires high luminous efficacy and brightness to ensure adequate illumination and maximize energy efficiency.

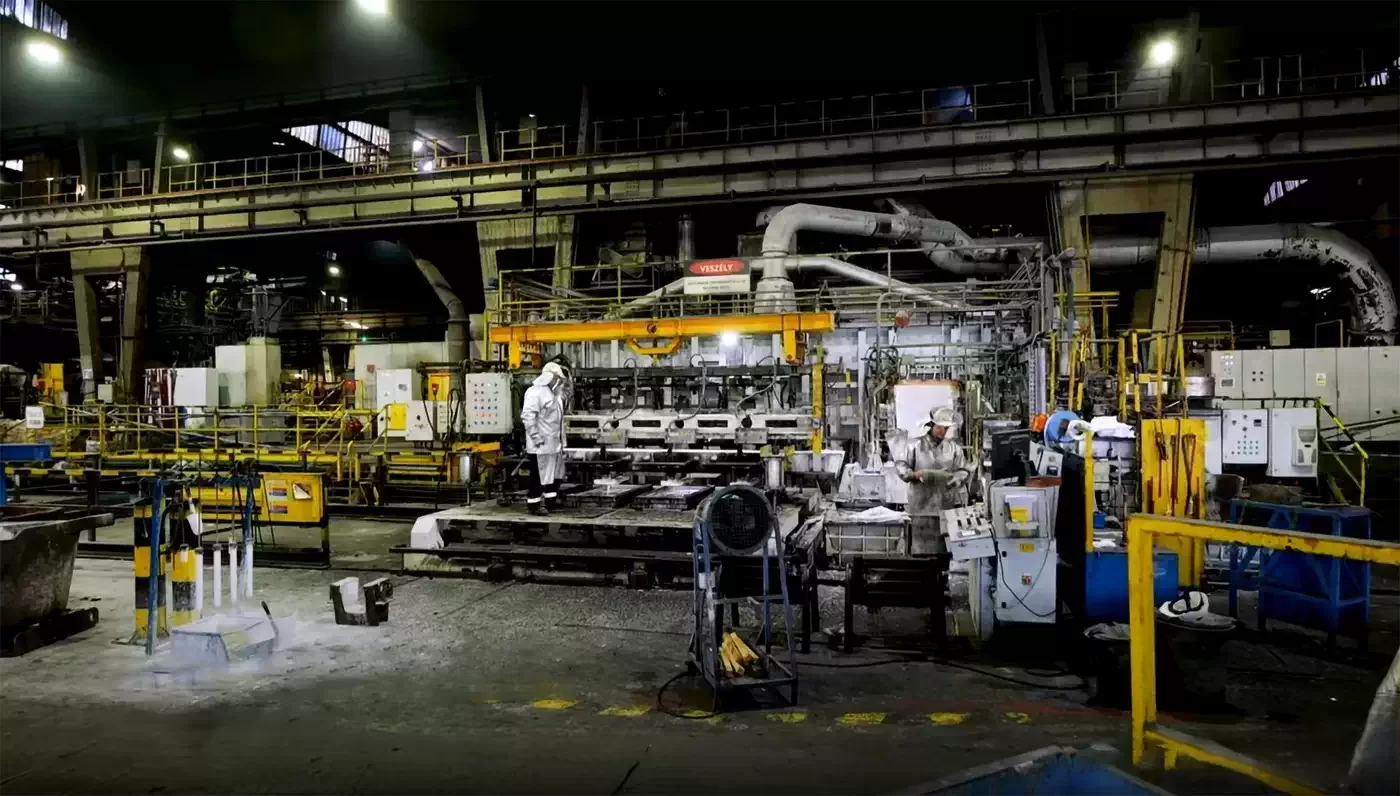

- “High-temperature” refers to work areas where ambient temperatures consistently exceed 55°C or even 75°C year-round, such as in steel mills, glass factories and injection molding workshops.

LEDRHYTHM 5000-hour high temperature test:

Structural Characteristics

They come in two common shapes: UFO round and long linear. They have different applications and are both excellent high temp high bay LED lights.

- UFO Round: The main body is a round die-cast aluminum heat sink with dense cooling fins on the back. The light source module is located in the center, covered by a glass or PC lens. The driver power supply is usually a separate module. They have high power and can evenly illuminate the entire area.

- Linear: These are long strips, similar to traditional fluorescent tubes, but with stronger power, brightness and structure. They are equipped with a long PC or glass cover for protection and secondary optical light distribution. They can be used in both indoor and outdoor high-temperature areas.

| Feature | Round | Linear |

|---|---|---|

| Light Distribution | Point-source, symmetric light spread | Line-source, symmetric or asymmetric along length |

| Application Area | Open square areas like central warehouse zones | Aisles or long corridor-type spaces |

| Space Efficiency | Single-point coverage, spacing needs calculation | Can be closely aligned for continuous lighting, no dark spots |

| Visual Experience | May cause glare at certain viewing angles | Softer light, generally more comfortable to the eye |

| Installation & Aesthetics | Traditional industrial look, single mounting points | Clean linear layout, can be aligned in rows |

Technical Highlights

Efficient heat dissipation: Separate the chip from the driving power supply; the UFO shape will increase the diameter to increase the heat dissipation area; select materials with better thermal conductivity.

High-temperature materials: Select LED chips with stronger heat resistance and less thermal attenuation, as well as high temp driving power.

Optics: Use professional glass lens that is resistant to high temperatures and not prone to aging or yellowing. Not an ordinary lens.

Temperature Range

Current high temp high bay LED lights on the market typically operate in ambient temperatures between 65°C and 85°C. These fixtures can generally meet the lighting needs of most high temperature workshops and factories in industrial field.

At LEDRHYTHM, we offer both 65°C and 75°C, with round and linear options available. We also support custom services that can withstand ambient temperatures up to 110°C. Feel free to contact us. Check out 65°C or 75°C high temperature high bay LED lights.

| Temperature Rating | Ambient Condition | Heat Source Level |

|---|---|---|

| 65°C Standard | Well-ventilated high bay areas | Low to Medium |

| 75°C Enhanced | Casting or forging zones with radiant heat | Medium to High |

| 75°C – 110°C Custom | Extreme furnace vicinity or continuous heat impact zones | High / Continuous Heat Radiation |

Application

As we mentioned earlier, these fixtures are designed for industrial areas with high ceilings and high ambient temperatures. In addition to excellent heat resistance and high lumen output, they also have a minimum IP65 rating, ensuring protection against water, dust and corrosion. This makes them suitable for a wide range of applications, including most harsh factory environments.

| Industrial Field | Typical Area | Recommended Temperature Rating |

|---|---|---|

| Steel & Metal Foundry | Casting lines, overhead crane zones | 75°C |

| Forging / Heat Treatment Workshop | Quenching and tempering furnace area | 75°C |

| Glass & Ceramics Production | Furnace top platforms, forming lines | 65°C – 75°C |

| Chemical or Petrochemical Sites | High vapor or enclosed heat zones | 65°C – 75°C |

2. High Temperature LED Flood Lights

High temperature LED flood lights are another major player in industrial lighting. Unlike the high bay lights mentioned above, they feature a wide beam angle, illuminating large areas. Combining wide flood lighting with heat resistance, they are primarily used in outdoor and indoor applications with high temperatures (>55°C).

Structural Characteristics

High temp LED flood lights are typically square in shape, featuring an adjustable metal bracket for multi-angle illumination. They can be mounted on walls, buildings or poles. They prioritize directional control and heat dissipation efficiency, resulting in the following structural features:

- Heat dissipation structure: Large heat dissipation fins on the back of the fixture body create a natural convection channel.

- Adjustable mounting bracket: Allows the fixture to adjust its illumination direction, flexibly controlling the beam according to changes.

- Modular light source and driver: Separating the light source from the power system enhances heat dissipation and extends overall life.

Technical Highlights

Heat Dissipation: This is the core of high-temperature floodlights, utilizing a heat sink made of highly thermally conductive aluminum. The light source and driver are separated to prevent heat from the light source from transferring to the power supply.

Higher protection: IP66 and above are standard for flood lights, meaning they are completely dustproof and can withstand strong water jets. Combined with high temperature characteristics, this allows them to cope with various extreme conditions without any pressure.

Heat-Resistant Components: These include better LED chips, driver power supplies, and heat-resistant glass lenses or reflectors.

Application

They are ideal for a wide range of applications, including high temperature or harsh outdoor environments requiring reliable illumination of large areas. LEDRHYTHM products offer this, with beam angles up to 120° and withstands ambient temperatures of 65°C. Learn more about 65°C high temp LED flood lights.

| Application Scenario | Indoor / Outdoor | Lighting Purpose |

|---|---|---|

| Steel Plants / Foundries | Indoor & Outdoor | High-intensity flood lighting for casting, smelting, material handling |

| Glass Manufacturing Facilities | Indoor | Stable illumination under radiant heat from furnaces |

| Cement Plants / Kiln Areas | Outdoor | Wide-area lighting for high-dust, high-heat working platforms |

| Port Terminals / Heavy Loading Zones | Outdoor | High-mast flood lighting for cranes and cargo handling positions |

| Boiler Rooms / High Heat Workshops | Indoor | Focused lighting to support maintenance and inspection |

3. High Temperature LED Vapor Tight Light Fixture

This is a type of waterproof and dustproof LED lights (Vapor Tight Light) used in high temperature environments. It adopts linear design to provide continuous, uniform and low-glare lighting. And its structure focuses more on sealing, corrosion resistance and heat resistance.

Structural Characteristics

High temp LED vapor tight light fixture adopts an integrated sealed design. The shell is made of aluminum alloy, with a high-strength PC cover and high-temperature resistant silicone sealing strips. It can effectively prevent steam, oil mist and dust from entering the interior of the fixture, and can withstand ambient temperatures above 65°C. You can learn more detailed articles about vapor tight light.

Key Features

High temperature: This is an improvement over the standard vapor tight light. Due to its sealed structure, heat dissipation is more difficult. It uses heat proof driving power and materials, as well as an additional aerodynamic heat dissipation duct design.

Dustproof & waterproof: This is core feature, and we can provide IP66/IP69K and IK10 ratings. The fully sealed structure provides the best protection for the fixture.

Anti-corrosion: The shell is made of high-strength, corrosion-resistant and aging-resistant materials, such as high-quality PC and special aluminum alloy, which can resist various chemical or salt spray corrosion.

Advantages

- This luminaire simultaneously meets the four most common challenges faced in industrial lighting environments (high temperature, waterproof, dustproof and corrosion-resistant).

- It maintains low light decay and a long lifespan even in high-temperature and harsh environments, ensuring excellent long-term operational reliability.

- Fully enclosed design significantly reduces malfunctions caused by dust, moisture or corrosive substances entering the fixture, reducing maintenance costs.

- Safe and Energy-Saving: LED technology is inherently energy-efficient, and this luminaire offers a high level of protection, ensuring production safety.

3 Types in LEDRHYTHM

At LEDRHYTHM, we offer the three high temperature LED lights mentioned above for industrial lighting, covering a variety of indoor and outdoor areas. They can withstand different ambient temperatures, but we can also accept customized requests for higher temperatures. Click to view.

| LEDRHYTHM Type | Available Temperature Levels |

|---|---|

| High Temp LED High Bay | 65°C / 75°C / up to 110°C custom |

| High Temp LED Flood Light | 65°C / custom |

| High Temp LED Vapor Tight | 75°C / custom |

Conclusion

The above three types of fixture can illuminate most high temperature industrial environments. They can meet different needs and scenarios. When selecting, first determine the high temp LED lights type based on the lighting scenario and requirements, then consider the ambient temperature. This ensures you have the best lighting solution for your project.

FAQ

Which type of high temperature LED light is right for me?

In actual industrial environments, choosing which type of high temp LED lights to use is not simply a matter of looking at the “temperature resistance”, but rather a comprehensive judgment based on the scene, installation height, and whether there is steam or dust.

- If you need to illuminate a large indoor space, high temp high bay is the preferred choice.

- For outdoor, flood lighting is more suitable.

- If the environment is not only hot but also humid, dusty or corrosive, choose vapor tight light.

How should I choose the temperature that a high temp LED lights can withstand?

A higher heat resistance rating isn’t necessarily better. You need to choose a temperature rating based on the ambient temperature of the fixture’s installation location to avoid are too high or too low. If the ambient temperature is 50-60°C, choose a 65°C rating; if it’s within 70°C, choose a 75°C rating.

Note: The temperature at higher points in indoor is higher than the ground temperature.

Do high temperature LED lights consume more electricity?

No, consume electricity depends on power. The higher the power, the more power it consumes. We can achieve a luminous efficacy of over 150lm/W, which means we can achieve the desired brightness with less power, improving energy efficiency.

Does lighting in high temperature environments require regular maintenance?

Yes, but professionally designed LED lights significantly reduce maintenance frequency, extending maintenance intervals from months to years.

What happens when ordinary LED lights are used in high temp environments?

Using ordinary LED lights in a high temperature environment will not stop working immediately, but many hidden dangers will arise.

- LED chips rapidly degrade, causing a drop in luminous flux and a phenomenon known as “getting dimmer with use.”

- Driver power overheating, will cause the fixture to flicker and go out frequently.

- Insulation failure, burned wiring and even short circuits and fires.

Will the life of high temp LED lights be shortened?

Usually not. They are designed for high temperature environments and have been tested for a long time. It will not affect the lifespan and can still maintain more than 50,000 hours.

But if the ambient temperature exceeds the temperature that the fixture can withstand, the light decay will be accelerated and the lifespan will be shortened.