LED Factory Lights

In various factories, there may be high temperature, humidity and metal dust. Excellent lighting system can improve production efficiency and reduce operating costs. We can provide high protection, high brightness and stable LED lighting solutions.

About Factory Lighting Environment

Factories differ from workshops or warehouses in terms of layout, operations, and environmental conditions. Factory lighting fixtures usually needs to illuminate a large and complex space, including multiple production areas, heavy machinery, continuous work and strict safety requirements. This also places higher demands on the quality and stability of light. In contrast, workshops are typically smaller and simpler in layout. You can refer to our page on workshop lighting.

Factory lighting fixtures must withstand harsher environments. For example, steel and glass mills must contend with high temperatures and metal dust; chemical plants must withstand corrosive gases and even water impact during cleaning. Consequently, they place even more stringent lighting requirements, demanding not only high brightness and uniformity but also durability, heat resistance, and high protection to ensure long-term, safe operation.

- Large manufacturing and assembly plants: Have spacious areas and high ceilings, with production areas often arranged in continuous layout. The focus of lighting is on achieving high illumination coverage and good uniformity.

- Precision machining and quality inspection factories: More stringent visual requirements, demanding high illuminance, high color rendering, and high color temperature. Precise identification of every detail and defect is crucial.

- Heavy industry factories: The environment is extremely complex, potentially involving mechanical impacts, high-temperature steam, and chemical corrosion. The protection and stability of LED lighting fixtures are paramount.

LEDRHYTHM - LED Lighting For Factories

LED high bay lights is essential for factory lighting, LEDRHYTHM also offers floodlights and vapor tight lights type for various areas. For general factories, energy efficiency and convenience should be prioritized. We recommend high-bay lights with high luminous efficacy of 190 lm/W or above, or equipped with sensors for automatic on/off switching, dimming, color temperature adjustment, and power control. These functions ensure low-cost, smart lighting.

However, in harsh factory environments, the primary consideration is the fixtures durability. They may face high temperatures, humidity, corrosion or vibration. LEDRHYTHM offers high temp lights operating at 65-75°C and housed in IP66/IP69K waterproof and corrosion-resistant housings. While their luminous efficacy is slightly lower than 190 lm/W, but they offer superior stability and reliability, ensuring that environmental factors do not degrade lighting quality or shorten their lifespan.

Which type of LED light is suitable for your factory?

- LED High Bay Lights: Have high lumen output and strong penetration power, can maintain sufficient ground illuminance and uniformity even at higher mounting heights. They are the main type of indoor industrial lighting such as factories, warehouses.

- LED Linear Lights: Linear light is continuous and uniform, ideal for work areas requiring continuous illumination and visual comfort, such as production and assembly lines. Particularly suitable for factory environment that require precise operations.

- LED Flood Lights: Using wide or asymmetrical beams, they are often installed on walls or poles for large-area supplementary lighting. They are the primary choice for facade and semi-outdoor, and has strong adaptability.

- LED Vapor Tight Lights: This is a special type of industrial-grade linear lighting fixture. It is named for its completely sealed structure and high protection performance. It is an excellent choice for harsh environments lighting in factories.

- LED High Temperature Lights: Designed specifically for high ambient temperatures. For factories with continuously high temperatures, such as those involved in metallurgy and casting, they operate reliably without dimming or damage.

LEDRHYTHM - LED Factory Lighting Manufacturer in China

At LEDRHYTHM, we specialize in LED lighting solutions for the industrial application. Leveraging extensive industry experience and comprehensive production systems, our products have been successfully deployed in over 20 countries worldwide. We can also customize luminaires to meet your specific needs, including higher luminous efficacy, component brand, and custom-designed lighting simulations. Illuminate complex factory environment by combining different types of lighting fixtures, and has excellent stability. All products come with 5-year warranty, LEDRHYTHM is your ideal LED factory lighting manufacturer.

| Key Aspect | Advantages |

|---|---|

| High Efficiency | High lumen efficacy ensures sufficient brightness for large factory spaces while reducing energy consumption. |

| Lighting Quality | Optimized optical design provides uniform illumination, minimizing glare and visual fatigue for workers. |

| Industrial Grade Housing | Robust die-cast aluminum or PC housing, along with excellent thermal management, ensures can withstand harsh factory environments. |

| High protection | Waterproof ratings are available in IP65, IP66, and IP69K, with resistance to salt spray or chemical corrosion, and impact resistance from IK08 to IK10 |

| Smart Control | Compatible with dimming, sensors and intelligent control systems to optimize based on actual usage. |

| Long Service Life | Long lifespan reduces maintenance frequency and total costs of lighting systems over their entire service life. |

Worker Comfort in Factory Lighting

- Glare control: Through high-bay installation, narrow beam angles, and lampshades, glare is effectively avoided. This allows the light is precisely distributed across the work area, reducing eye strain.

- Uniformity: Optional professional optical lenses and frosted diffusers provide more uniform light distribution, and combined with appropriate layout spacing, prevent noticeable dark areas on the ground.

- Illuminance: High illuminance also improve visual comfort and clarity. Our LED lighting series meets various brightness requirements and supports dimming, flexible control is possible as needed.

Installation Methods

In factory lighting design, the installation method of luminaires usually needs to be determined based on the building structure and lighting requirements. LEDRHYTHM offers a variety of flexible mounting options, which are not only easy to install but also structurally robust. Ensure luminaires adapt to different ceiling heights and layouts:

- Surface Mount: Stable installation and simple wiring.

- Suspended Mount: Secured by chains, allowing for flexible height adjustment.

- Side Wall Mount: Suitable for production lines and aisles requiring side lighting.

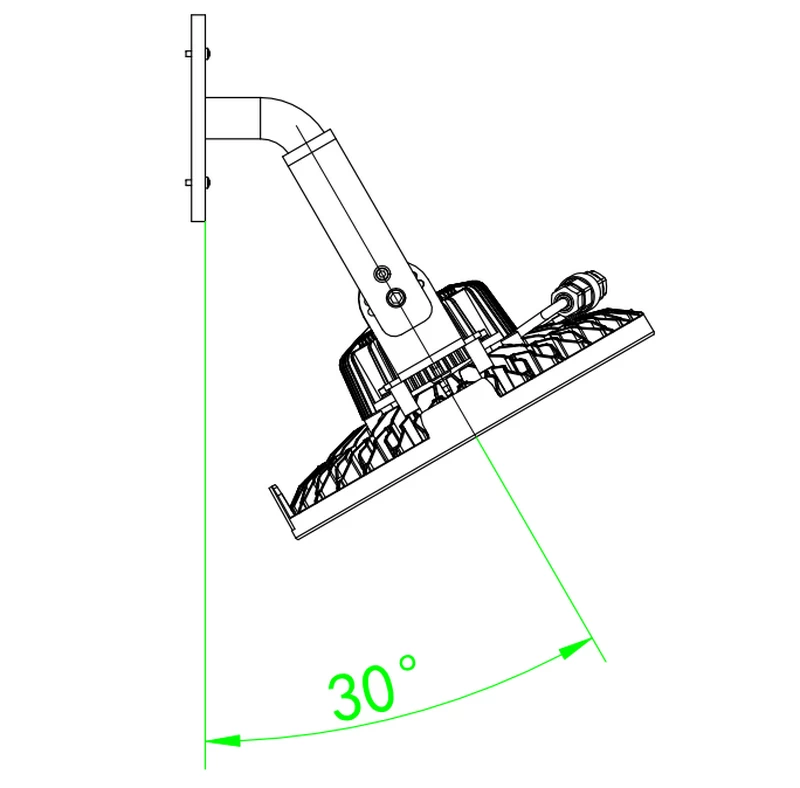

- Bracket Mount: Easy angle adjustment, ideal for factory areas requiring directional lighting.

LEDRHYTHM - Smart LED Factory Lights

With the advancement of factory automation, lighting systems are gradually shifting from traditional manual switches to more flexible and efficient intelligent systems. Smart LED factory lights not only provide convenience in management but also optimize energy consumption and reduce long-term operating costs. Through 0-10V/DALI dimming or wireless control systems, lights in different areas can be grouped and managed to achieve batch dimming and scene switching. Optional motion sensors for human presence and light sensing enable the lights to turn on only at night or when people are present, effectively saving energy. You can even remotely monitor the lighting status of factory and flexibly adjust it according to production needs.

You can learn more about smart lighting systems or 0-10V dimming.

| Smart Feature | Benefits |

|---|---|

| Motion Sensor | Automatically adjusts lighting based on sensors, reducing energy use in low-traffic factory areas |

| 0-10V / DALI-2 Dimming | Precise brightness control and zoning, allows for flexible changes in illuminance levels |

| Tunable Color Temperature | Adjustable color temperature helps adapt to changing lighting needs |

| Remote Monitoring & Control | Centralized control allows managers to monitor and manage lighting systems remotely and efficiently |

| Scheduled Lighting | Avoid forgetting to turn on the lights or turning them on too early, while avoiding unnecessary energy waste |

How high should LED factory lights be installed?

The installation height of LED factory lights is determined by ceiling height and required illuminance. Higher ceilings typically require higher installation heights and higher wattage. The higher the illuminance requirement, the higher the wattage, and the higher the installation height. The beam angle and total lumen output of luminaire also directly affect the choice of installation height. Narrow beams are more suitable for higher installation positions to concentrate the light and avoid insufficient brightness; while wide beams are more suitable for spaces with medium to low heights, helping to improve uniformity.

At LEDRHYTHM, we offer a wide range of wattage options, meaning our luminaires can be installed at a variety of heights, eliminating the need to worry about your factory being too high or too low.

| Ceiling Height | Recommended Wattage |

|---|---|

| 6–8 m (20–26 ft) | 100–200W |

| 8–10 m (26–33 ft) | 200–300W |

| 10–15 m (33–50 ft) | 300–500W |

Are LED high bay lights suitable for all factory lighting applications?

Yes, with its flexible beam angle, wide power range, and proven industrial design, LED high bay lights can be used for a variety of lighting needs, from general manufacturing to heavy-duty factories. Firstly, they can be installed at various heights and meet wide range of illuminance standards. Secondly, they are highly adaptable to different environments, typically possessing good dustproof, waterproof, and shock-resistant, enabling them to operate stably for extended periods in dusty, humid, or corrosive environments. Even in high-temperature factories, with hot steam or smelting processes, we still have specially designed high temp high bay LED lights to meet the requirements.

While they are highly adaptable in factory lighting, in actual projects they may still need to be combined with other types of luminaires to create more rational and efficient complete lighting solution.

Can LED factory lights withstand the impact of water jets?

Generally, as long as the protection rating reaches IP65 or higher, it can effectively withstand low-pressure water jets from different directions and is suitable for cleaning and humid areas.

However, for factory areas requiring frequent, high-intensity water rinsing, it is recommended to choose vapor tight lighting fixtures with higher protection rating and more sealed structure, such as our IP69K. The design details have been enhanced with improved sealing, breather, and wiring protection to cope with continuous water flow impact and temperature changes.

| IP Rating | Protection | Use |

|---|---|---|

| IP65 | Dust-tight and protected against low-pressure water jets. | General factories and areas with occasional water exposure. |

| IP66 | Dust-tight and resistant to strong water jets. | Washdown areas and factories with frequent cleaning. |

| IP69K | Withstands high-pressure, high-temperature water jets. | Hygienic factories requiring intensive washdown. |

How much energy can be saved by replacing traditional factory lighting with LED lights?

Modern LED lighting emits 50-70% more light per watt than traditional lighting, so LED lights only require very low wattage to achieve the same brightness. Generally, the higher the wattage of factory old lighting fixtures, the more significant the energy savings after replacing them with LED. For example, replacing 800W MH with 300W LED can save 500W of energy consumption. The longer the daily operating time, the greater the long-term energy savings will be.

For example, for 50 fixtures operating for 10 hours a day, 300 days a year:

- 80W LED replacing 200W MH, annual savings: 120W × 50 × 10h × 300 ≈ 18,000 kWh

- 150W LED replacing 400W MH, annual savings: 250W × 50 × 10h × 300 ≈ 37,500 kWh

- 200W LED replacing 500W MH, annual savings: 300W × 50 × 10h × 300 ≈ 45,000 kWh

- 300W LED replacing 800W MH, annual savings: 500W × 50 × 10h × 300 ≈ 7,5000 kWh

Does installing LED factory lights require replacing the old electrical circuit?

LED factory lights typically support a wide range of input voltages, from AC100 to 277V and even up to 480V, allowing them to be directly adapted to existing wiring. As long as the old wiring meets basic safety standards and can provide stable power supply, the lights can be replaced directly. However, if the existing wiring is severely aged, has inadequate insulation or safety standards, or requires the addition of 0–10V or DALI-2 dimming system, then the circuit needs to be adjusted or upgraded.

What level of illuminance is required for factory lighting?

Visual perception varies significantly under different illuminance levels. 100–200 lux provides softer environment, suitable for movement and simple tasks, but prolonged use for detailed work can easily lead to fatigue. 200–300 lux provides clear and natural environment, representing the most comfortable and common brightness range in most factory workshops, balancing efficiency and quality. Above 400–500 lux, contrast is stronger, details are more apparent, helping to reduce errors and improve concentration, but glare needs to be controlled.

| Area | Typical Tasks | Recommended Illuminance |

|---|---|---|

| Material storage area | Bulk storage, forklift operation | 100–150 |

| General production area | Manual assembly, machine operation | 200–300 |

| Heavy manufacturing area | Metal processing, large equipment operation | 200–300 |

| Precision assembly line | Electronics assembly, fine components | 300–400 |

| Inspection & quality control | Visual inspection, defect detection | 400–500 |

| Maintenance & equipment room | Repair, inspection, servicing | 200–300 |

| Corridors & walkways | Personnel movement, safety passage | 100–150 |

How can factory LED lighting systems reduce long-term operating costs?

Choosing high luminous efficiency LED lights is fundamental, as they can provide higher lumen output at the same wattage, ensuring sufficient brightness while minimizing electricity costs. Secondly, integrating dimming system allows for dynamic adjustment of brightness based on actual needs, such as 0–10V and DALI dimming, common choice for factory lighting. Can reducing power output and thus lowering overall energy consumption costs. Motion sensors can also be added to automatically turn the lights on and off based on human activity, further reducing unnecessary energy consumption.

Does factory lighting require lighting simulation or design support?

We highly recommend conducting lighting design or simulation. If you choose and install light fixtures arbitrarily, the most common result is uneven illuminance, failing to achieve the desired lighting or visual effect. Through lighting simulation and professional design, the actual lighting effect, including illuminance and uniformity, can be clearly displayed before the luminaires are installed. This helps determine the most suitable wattage, layout, and quantity of LED factory lights, avoiding secondary construction later and reducing project costs.