Quality Control

We maintain a strict attitude towards the quality of each product. Formal or excellent LED lighting manufacturer will conduct multiple systematic tests and keep complete records before the product is launched on the market. Ensure that each fixture has the ability to operate stably in the long term.

This is a standard practice in the industry, especially in application scenarios with high requirements such as industrial, commercial and sports lighting. Therefore, we have built a complete full-process quality control system, from raw materials to final packaging, every step is traceable, testable and verifiable.

Raw Material Screening and Supply Chain Management

We have established long-term partnerships with leading international and domestic suppliers of chips, drivers, and optical materials. All suppliers undergo qualification review and sample verification, and sign consistency and stability quality agreements. All LED chips, drivers, electrolytic capacitors, lenses, aluminum materials, and sealants must pass tests for luminous efficacy, temperature resistance, solder joint quality, thermal conductivity, and corrosion resistance before they are allowed into storage.

1. Incoming material inspection

Inspect incoming materials according to material inspection specifications, parts approval letter or control plan requirements, and record inspection results in incoming inspection report. The company does not allow emergency release, and shall not release any incoming materials before the inspection is completed.

2. Process inspection

According to the frequency and requirements specified in the inspection specification or control plan, the output products of the production process shall be randomly inspected, and the important characteristic parameters of the equipment shall be inspected, and the inspection results shall be recorded in the corresponding forms.

3. Test inspection

After the production of the product is completed, the final inspection or test of the product shall be carried out according to the requirements of the inspection specification or control plan before storage, and the inspection or test data and results shall be recorded.

4. Shipping inspection

Before the product is delivered to the customer, the pre-shipment inspection of the product shall be carried out according to the inspection specification or the customer’s requirements, and the inspection result shall be recorded.

Product Testing

We have a complete product test record system (including Excel and test software data), and save test photos, original reports, third-party certification certificates, and can provide technical white papers, test curves, IES files, etc. to customers. If you need data on a certain lighting product, you can find the answer on the product page. If you can’t find it, you can contact us at any time and we will contact you again.

We have up to 30 test items. The following lists some common tests and some test equipment. If you have any questions about our tests, you can contact us to answer them.

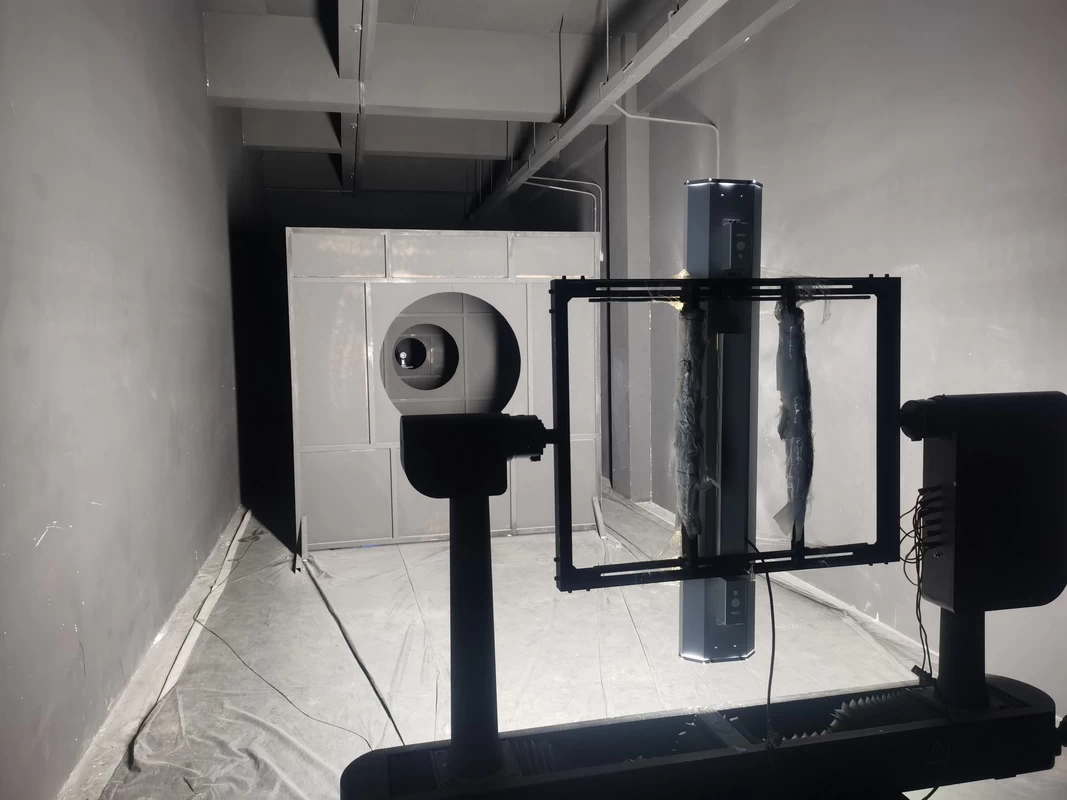

1.Light distribution test (light distribution curve/IES test)

Evaluate the uniformity of lighting, glare control and illumination range of lights

2.Integrating sphere test

Detect core parameters such as luminous flux (lm), luminous efficacy (lm/W), color temperature (CCT), and display index (CRI) of lights

3.Life test/aging test

Verify the stability of lights in long-term use to ensure that they meet standards such as L70/L80/L90

4.IPX5/IPX6/IPX7 waterproof test

Verify the protection of lights against rain, flushing or short-term immersion in water, suitable for outdoor, port, stadium and other scenes.

5.Salt spray test

Simulate use at the seaside or in a highly corrosive environment (such as docks and chemical plants) to detect the corrosion resistance of the lights coating and structure.

6.Glow-wire test / Needle flame test

Test the flame retardancy of the shell material, which is a necessary item in safety regulations (such as UL, EN)

7.Wind resistance test

It is crucial for high pole lights, stadium lights and other wind resistance performance, and evaluates whether the shape of the lights has aerodynamic characteristics

8.Vibration test

Detect the structural stability of lights during transportation, hoisting, and outdoor vibration (such as bridges and highways)

9.High and low temperature test / Constant temperature and humidity test

Verify the adaptability of lights in extreme climates (such as plateaus, deserts, and cold areas)

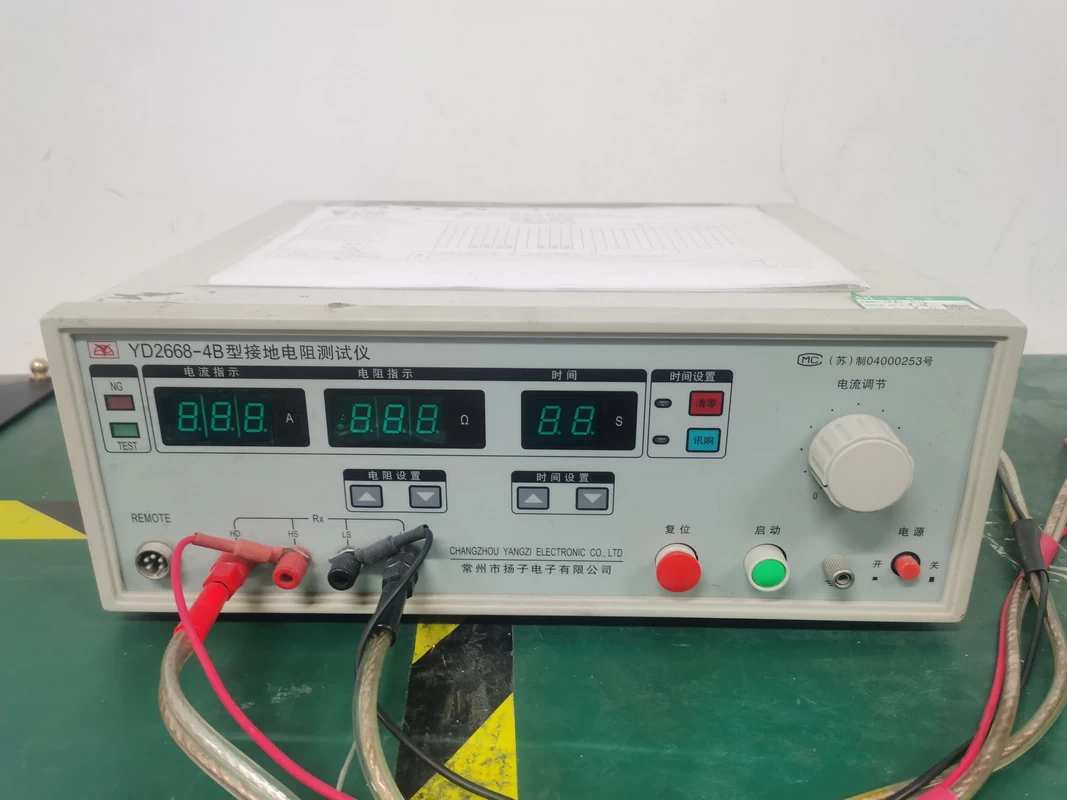

10.Safety test (including ground resistance and leakage test)

Detect electrical safety to avoid hidden dangers such as leakage and short circuit

11.ROHS test

Verify whether the lamp material contains harmful substances (such as lead, mercury, cadmium) and meets environmental protection requirements

12.Power test / power meter

Detect the measured power, power factor (PF), harmonics (THD), etc. to ensure driving efficiency