Table of Contents

ToggleIntroduction

Steel mills are widely recognized as one of the most challenging lighting environments in the industrial area. Sustained high temperatures severely impact the performance and lifespan of fixtures. So, selecting LED high bay lights that can withstand high temp and possess high protection is crucial for steel mill lighting.

Leveraging years of experience in industrial LED lighting, LEDRHYTHM has provided complete lighting solutions for numerous large steel mills. This article will explore these.

Lighting Challenges in Steel Plant

- High temperatures: This is the primary challenge. Ambient temperatures in steel mills can easily exceed 70°C, with some areas reaching 100°C. Prdinary high bay LED lights cannot function properly and their lifespan is shortened.

- Steel mill air is heavily contaminated with dust, metal oxides, smoke and corrosive gases, which can easily enter the interior of fixtures or corrode their housing.

- The passage of heavy vehicles and the operation of large equipment will cause strong vibrations and mechanical shocks, which may cause fixture screws to loosen, brackets break and internal electronic components to be damaged or fail.

- Steel mills LED lights often operate for 12 hours without interruption, requiring them to have an extremely long lifespan and extremely low maintenance.

- Steel mills are large and complex spaces. High ceilings, typically between 12 and 25 meters, require higher-power lighting fixtures with strict requirements for beam angle and illumination uniformity to ensure operational safety and visual comfort.

High Temperature High Bay LED Lighting Solutions

After gaining a thorough understanding of the steel plant on-site environment and lighting requirements, LEDRHYTHM team defined lighting objectives: achieving high brightness, safety and stable lighting in high temperature, dusty and high-bay space. And also required maximum energy efficiency.

Fixture Selection and Installation Methods

We recommend using professional high temp high bay LED lights, which are excellent industrial lighting fixtures. Not only can they withstand higher ambient temperatures(65+℃), they can also provide brighter light in high ceiling spaces like factories. They are the best choice for steel mill lighting.

At LEDRHYTHM, we offer high temperature high bay LED lighting for different ambient temperatures. We currently have two mature products that can withstand ambient temperatures of 65°C and 75°C, and we can also customize models for temperatures up to 110°C.

- Excellent Heat Resistance: Fixture operates stably in consistently high temperatures, ensuring uncompromised lighting quality and lifespan.

- High Efficacy and High Lumen Output: Utilizing advanced LED chips and lenses, we have luminous efficacy of 160 lm/W and high output power exceeding 200W. Saves over 60% energy compared to traditional fixtures at the same illumination level.

- High Protection: Die-cast aluminum integrated design achieves IP65, surge protection and effective dust, shock and corrosion resistance.

- Optical Design: Equipped with highly heat-resistant lens, offers variety of beam angles (45°, 60°, 80° and 120°) to meet diverse needs.

- Long Life: Over 50,000 hours of life, even in high temperature environments, makes it suitable for long-term continuous operation.

Installation:

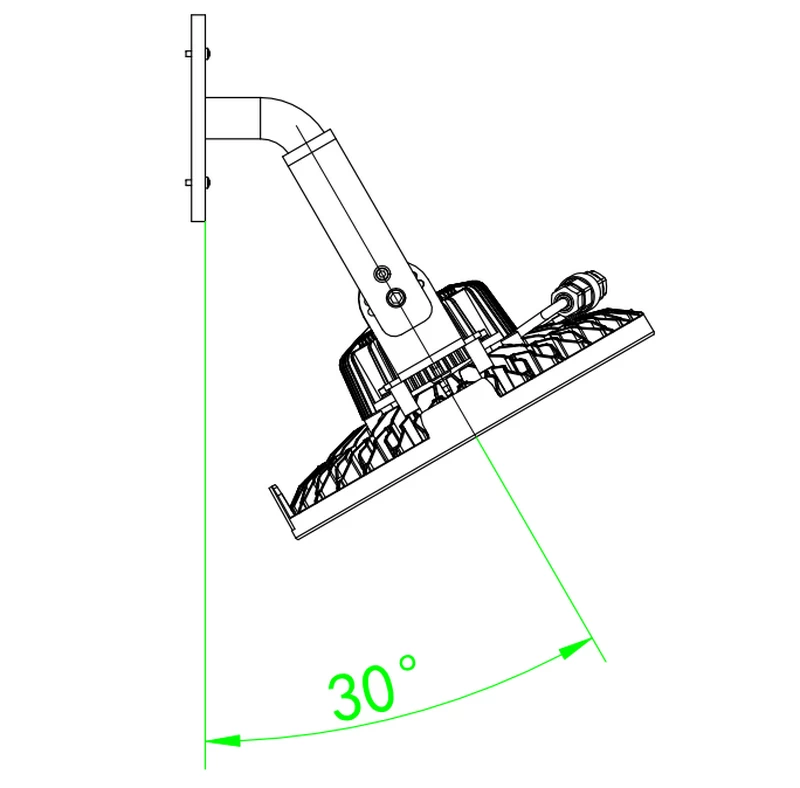

To accommodate the complex architectural structure of the steel plant, LEDRHYTHM high temp high bay LED lights supports ceiling-mounted, suspended (chains and rods), wall-mounted and adjustable bracket installation.

Power and Mounting Height

High temperature high bay LED lighting requires choosing the optimal power and mounting height, ensure brightness in steel plants while further improving energy efficiency and cost savings.

| Steel Mill Area | Mounting Height | Power Range | Illuminance (avg) |

|---|---|---|---|

| Steelmaking & Furnace Area | 18–22 m | 200–240W | 250–280 lux |

| Rolling & Processing Area | 14–18 m | 150–200W | 220–250 lux |

| Warehouse & Loading Zone | 10–15 m | 80–150W | 180–210 lux |

Heat Resistance and Heat Dissipation

High temp high bay LED lights must adopt high temperature resistant designs and materials, combined with excellent heat dissipation performance, in order to operate stably in high temperature spaces such as steel mills.

- Use high-quality, heat-resistant LED chips and lenses.

- LEDRHYTHM self-developed high-temperature resistant driver.

- Highly thermally conductive, flame-retardant silicone seals and silicone circuitry.

- Heat dissipation gap is provided between driver and fixture body.

- Die-cast aluminum housing, and enhanced heat sink fin area.

Furthermore, these high bay LED lights must pass rigorous high temperature testing, ensure stable light output during continuous operation. This robust heat resistance is the key to LEDRHYTHM long-term leadership in high temp lighting.

Benefit Analysis

Upgrading from ordinary high bay LED lighting to high temperature high bay lighting will solve all the pain points of steel plants. Including improved reliability, reduced maintenance costs and risks, enhanced safety and quality assurance and improved overall energy efficiency.

- Illumination increased by approximately 45%, raising the average illumination level in the steel plant from 180 lux to 260 lux.

- Energy consumption decreased by over 40%, significantly saving energy at the same brightness level.

- Maintenance requirements were reduced by over 70%, significantly saving labor and downtime costs.

- Illumination is more uniform, eliminating noticeable glare and dark areas, improving operator safety.

| Steel Plant Lighting | Regular LED High Bay | High Temp LED High Bay | Improvement |

|---|---|---|---|

| Ambient Temperature | -20°C ~ 45°C | -30°C ~ 75+°C | Withstands extreme heat |

| Average Lifetime | Shortened to 20,000 hrs | >50,000 hrs | Up to 70% longer lifespan |

| Fault | Yellowing, deformation, flickering, short circuit | No trouble | Reduced maintenance cost |

| Light Efficiency | Reduced to below 120lm/W | 150–160 lm/W | ~25% higher efficiency |

| Energy Saving | More and more power consumption | Maintain stability | Lower operating cost |

Real Project Case

Project: Shanghai BaoSteel High Temp High Bay LED Lighting Retrofit

Shanghai Baosteel is one of China’s leading steel manufacturers. Its steelmaking workshops are exposed to extreme environments of high temperature, high dust and high vibration for long time.

- Fixture: LEDRHYTHM 75°C high temp high bay LED lights

- Power: 200W

- Beam Angle: 60°

- Ambient Temperature: Approximately 70°C

- Installation Height: 15m

- Quantity: 160

- Illuminance: 380 lux

After three months of continuous operation at 70°C, the fixtures remained stable and trouble-free. Uniformity improved by 37% compared to the original lighting system, while overall energy consumption decreased by approximately 42%. The maintenance cycle was extended from every six months to over four years of maintenance-free.

The Baosteel project manager said that the electricity bill can be saved by about RMB 120,000 per year, the brightness also is significantly improved.

Conclusion & Call to Action

For high temperature factories like steel, foundry and glass production, it’s crucial to choose LED lighting that can withstand the corresponding ambient temperatures. This improves lighting efficiency and saves costs, while also directly impacting production safety.

LEDRHYTHM can customize high bay LED lights with temperatures up to 110°C, as well as other high temp lighting types for you to choose from. View our complete catalog or contact us for a free lighting solution.

FAQ

What happens if ordinary high bay LED lighting is used in high temperature steel plants?

The core components of ordinary high bay LED lights (such as the driver, electrolytic capacitors and chip solder joints) are prone to overheating, accelerated light decay and even failure in environments exceeding 50°C.

- Significant brightness degradation: Light will become dimmer over time.

- Power failure: Driver circuit can easily burn out or enter protection mode under high temperatures, causing the fixture to flicker or go out.

- Accelerated structural aging: Lenses, plastic components and sealants can age due to high temperatures, reducing the protection level.

- Increased maintenance costs: Frequent fixture replacement and production interruptions result in increased maintenance costs and downtime losses.

What costs can be saved by using high temperature high bay LED lighting?

Maintaining luminous efficiency of over 150lm/W even in high temperature environments, saving operating costs; High temp high bay LED lights require no replacement or maintenance for over 50,000 hours, saving maintenance costs; Stable, flicker-free lighting improves safety and operational efficiency, reducing hidden costs caused by production interruptions.

Does high temp high bay LED lighting require additional heat dissipation channels?

High temp high bay LED lights typically require no additional heat dissipation channels as their design is optimized for hightemperature environments. They feature highly heat-resistant materials and an excellent heat dissipation structure. Furthermore, we’ve tested them in confined spaces and ensure they’re designed for high ambient temperatures, eliminating the need to worry about damage.

What is the voltage range of your high temp high bay LED lights?

LEDRHYTHM high-temperature fixtures feature a wide voltage input design, compatible with a variety of industrial power supply standards, meeting the requirements of most industrial power grids worldwide (such as China’s 220V, Southeast Asia’s 230V, and the United States’ 277V). This provides great flexibility for lighting replacement.