LED Warehouse Lighting

There are many types of warehouses, lighting needs to not only energy efficient but also improve worker safety and efficiency. We offer 60W to 400W LED lights for warehouse use, ensure high uniformity and long-term operational stability.

Warehouse lighting is a crucial and common component of industrial lighting. It improves the efficiency of modern logistics and cargo storage. Traditional lamps are gradually being phased out, and modern LED technology has solved many of the problems that once plagued warehouse lighting, significantly reducing long-term operating costs while also improving light quality.

- LED High Bay Lights: Used for general lighting in warehouses with medium to high ceilings, their high lumen output and different light distribution allow them to provide sufficient illumination even at high mounting heights. We can also be used in cold storage.

- LED Flood Lights: Possessing strong directional lighting capabilities, they are often used as supplementary or functional lighting, suitable for entrance/exit, loading areas, outdoor or semi-outdoor warehouse.

- LED Vapor Tight Lights: Featuring higher protection ratings and a sealed structure, they can operate stably in humid, dusty, and corrosive environments, and are also the best choice for walk in cooler and freezer.

Pain Points of Warehouse Lighting

Warehouses, as key areas for logistics and production storage, feature large spaces, high shelves, and complex operations. They place higher demands on lighting. Otherwise, shadows and dark areas can affect safety and efficiency. In actual use, lighting often faces the following common difficulties:

- High Spaces

Ceilings are typically over 8–15 meters high. Higher installed lighting fixtures can easily cause dark areas and uneven illumination in areas below. - Dense Shelves, Severe Obstruction

Warehouse shelves are high and numerous, and their layout easily blocks light, especially in narrow hallway, where dark corners can easily appear, hindering workers’ picking and handling. - Multiple Operation Areas

Not only have storage areas, but also packaging, sorting, and loading/unloading areas. Each area has different requirements for brightness and color temperature. - Complex Environments

Some specialized area environments, such as those with high temperatures during the hot summer, as well as humidity and dust interference. These conditions also place certain requirements on the protective performance of LED lights.

LEDRHYTHM - LED Warehouse Lighting Manufacturer in China

LEDRHYTHM has provided lighting replacement and new built services to hundreds of around the world. As an LED warehouse lighting manufacturer with more than ten years of experience, we can help our customers achieve more flexible, safer and more energy-efficient lighting solutions.

At LEDRHYTHM, first of all, lighting must be energy-efficient to the greatest extent possible. We achieve luminous efficacy of 180-190lm/W for LED lights, consuming less electricity at the same brightness. Furthermore, Luminaires are rated for IP65/IP66/IP69K waterproofing and IK08/IK10 shock resistance. Also offer LED series that can withstand both high and low temperatures, ensuring continuous and stable operation regardless of your warehouse environment.

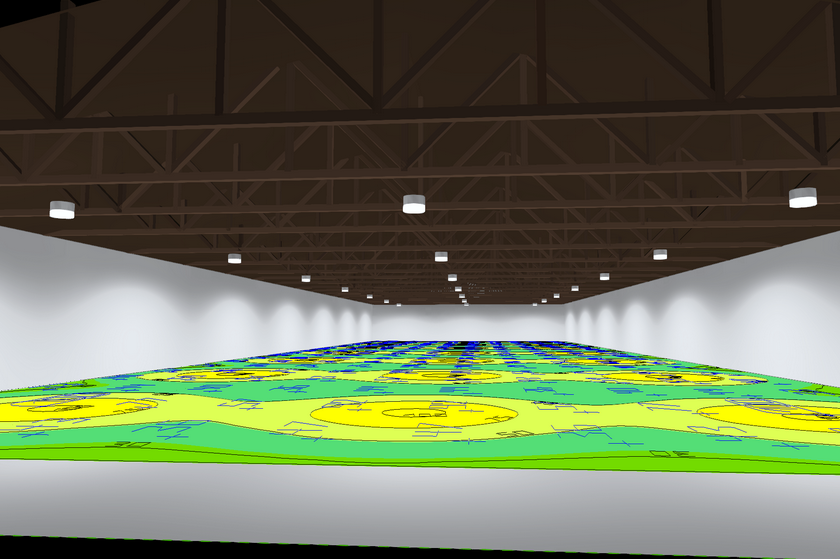

If you’re unsure how to choose the right LED lighting fixtures, or even how bright the lighting should be, we can provide lighting design services based on your venue and needs. We’ll recommend the most suitable parameters and layout, and inform you of the expected lighting effect. Please feel free to contact us to share your ideas.

Warehouse LED High Bay Lights

Whether it’s an industrial or commercial warehouse, they typically have high ceilings and large areas, LED high bay lights are the most mature and reliable choice for both general lighting and local lighting. UFO round is compact in size and flexible installation method, making it suitable for warehouses with scattered fixture layouts or those requiring rapid renovation. It covers wider lighting range with small number of lights. Linear design series have longer luminous surface, uniform and soft lighting effect still can be achieved through continuous layout. For aisle areas between higher shelves, the modular linear LED high bay light is the ideal choice, offering a variety of narrow beam angles to precisely illuminate aisles, corridors, and shelves, avoiding wasted light.

- Can illuminate warehouse with 6-18 meter high ceilings, with high light efficacy and a wide range of power options.

- Available in a variety of narrow and wide beam angles to cover different areas.

- Equipped with optical lens or PC diffuser to effectively reduce glare and improve workers’ eye comfort.

- 0-10V/DALI2 dimming as standard, and optional motion sensors and Zigbee systems can be used to achieve smart lighting.

- Installation method supports bracket mount, side wall mount, surface or suspended to adapt to different warehouse structures.

| Aspect | UFO High Bay | Linear High Bay |

|---|---|---|

| Warehouse Use | General, overall warehouse lighting | Aisles, racks, or overall |

| Light Pattern | Symmetric beam | Linear beam; narrow or wide |

| Layout Style | Single-point fixtures | Continuous or row layout |

| Coverage Capability | Covers open areas well | Can replace UFOs with wide-beam layout |

| Adaptation to Racks | Limited control between racks | Better control along racks |

| Installation | Fast and simple | Needs basic layout planning |

| Best Fit When | Simple layout, quick upgrade | Flexible layout or mixed zones |

LED Warehouse Lighting With Motion Sensor

Integrating motion sensors into LED warehouse lighting has become a common practice for improving energy efficiency and operational flexibility. Unlike manually switched lighting systems, sensor-controlled lighting automatically responds to the movement of people or forklifts, better reflecting the actual usage patterns in warehouse.

Many areas, such as shelving and storage areas, are not continuously occupied and are typically used intermittently. By configuring motion sensors, the lights can dim or turn off when no one is present, and then quickly return to the preset brightness when movement is detected, eliminating the need for manual management and significantly reducing unnecessary energy consumption.

At LEDRHYTHM, both LED high bay lights and vapor tight lights can be equipped with microwave or infrared sensors to reduce unnecessary lighting time or eliminating the hassle of manual control, thus extending the lifespan of the fixture and driver. This is undoubtedly the best choice for warehouses that operate for long periods but do not require continuous work.

Warehouse Height and Brightness

As warehouse ceiling height increases, light needs to cover larger space and overcome longer illumination distances, placing higher demands on individual fixture lumen output and light distribution. If the brightness and lumen output of LED high bay lights are insufficient, the floor will appear dim and uneven, directly affecting operational efficiency and work safety.

The warehouse ceiling height does not represent the luminaires installation height. So, the required lumens per fixture need to be determined based on the actual installation height and illumination requirements, and with appropriate beam angles, to ensure that the light effectively reaches the ground and goods. Lower installation heights are more suitable for wide beam angles to achieve uniform coverage; while higher installation heights require higher lumen output and require medium or concentrated light distribution to reduce light loss and glare. Learn the brightness details of warehouse LED high bay lights.

In taller warehouses with low goods stacking heights or low shelving, using extra-long suspension to reduce the actual installation height of light fixtures is a common practice. This allows for the selection of fixtures with lower lumens and wattage outputs, avoiding cost and energy waste. Care must be taken to prevent forklifts or other equipment from colliding with the light fixtures.

| Mounting Height | Beam Angle | Lumens per Fixture | Use |

|---|---|---|---|

| 4–6 m (13–20 ft) | 120° | 8,000–10,000 lm | Low racks, low storage areas |

| 6–8 m (20–26 ft) | 90°–120° | 10,000–20,000 lm | General warehouse lighting |

| 8–10 m (26–33 ft) | 80°–90° | 20,000–30,000 lm | High bay storage, mixed operations |

| 10–12 m (33–40 ft) | 45°–60° | 30,000–50,000 lm | High racks, large space |

LED vs Traditional Lighting

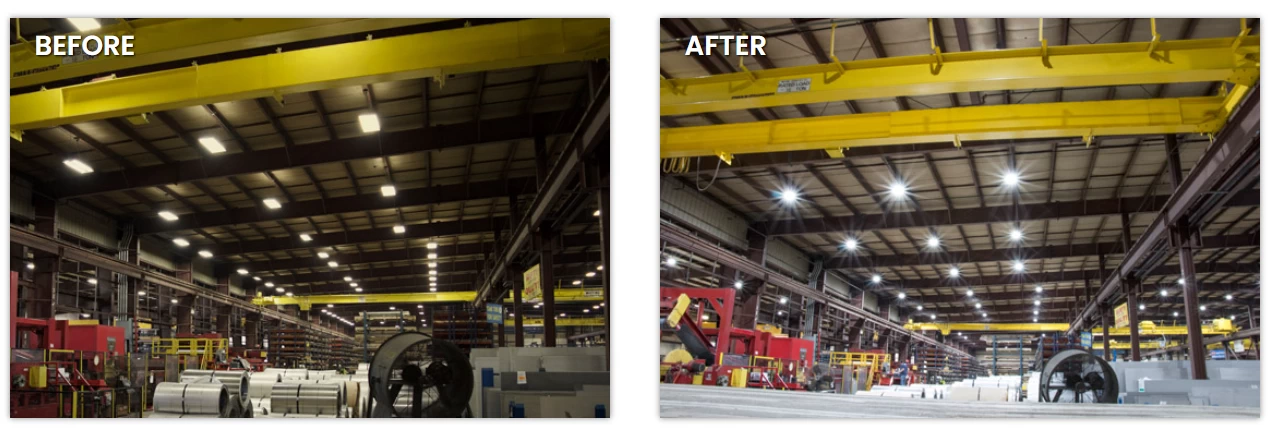

In the past, warehouse lighting used traditional fixtures including metal halide, HPS, or fluorescent lamps. These not only consumed a significant amount of electricity, but also required warm-up upon startup, had poor color rendering and required frequent maintenance. This reduced efficiency and resulted in high lighting costs.

In contrast, LED warehouse lighting overcomes all the shortcomings of traditional lamps, including high bay and low bay series, and improves the quality and uniformity of light. LED can reduce energy consumption by 60-70%. Although the initial cost is higher, the long-term operating costs are greatly reduced.

| Feature | Traditional Lighting | LED Warehouse Lighting |

|---|---|---|

| Lifespan | 10,000–20,000 hours | 50,000–100,000 hours |

| Equivalent Wattage | 400W Metal Halide ≈ 150W LED | 150W LED replaces 400W MH |

| Protection Rating | IP20–IP40 | IP65–IP66 |

| Maintenance | Frequent replacement, high labor cost | Minimal maintenance |

| Light Output | Decreases over time | Stable light output |

| Warm-up Time | Slow or delayed start | Instant full brightness |

| Uniformity | Uneven, shadow-prone | More uniform lighting |

| Control & Dimming | Limited or not available | Dimming and smart controls |

Lighting Recommendations For Different Areas

- Main Storage Area/High Racks: Primarily used for storing goods and forklift traffic, lighting should prioritize overall brightness and longitudinal visibility. LED high bay lights should be used to avoid noticeable dark areas.

- Picking and Sorting Areas: Require higher visual clarity and need uniform, stable, and comfortable lighting. Compared to simply pursuing high brightness, it is more important to reduce glare and shadows, and color temperature of 5000K or higher is recommended.

- Loading and Unloading Areas: Typically located near warehouse entrances and exits, these areas have more complex of personnel and vehicles. Lighting needs to consider both safety and directional guidance. In addition to overall lighting, LED floodlights can be used for targeted supplementary lighting.

- Cold Storage: Temperatures can be as low as -40℃, requiring the use of low-temperature-specific high-bay lights or vapor tight lights with good sealing structures and breathable designs to cope with condensation.

- Warehouse Exterior Walls: Lighting is needed to improve nighttime visibility and safety. LED floodlights provide evenly distributed light and can be installed on walls or poles to improve safety monitoring and visibility for vehicles entering and exiting.

- Humid and Frequently Cleaned Areas: In environments such as food, chemical warehouses, or cleaning passages, lighting stability is more critical than brightness. LED tri-proof lights can effectively resist moisture, dust, and pollutant intrusion, preventing damage to the luminaires.

Warehouse Illuminance

Illuminance (lux) is an important indicator of lighting brightness. In warehouse lighting, illuminance affects visibility and comfort. Generally speaking, higher illuminance indicates brighter light, allowing for clearer visibility of shelves and product labels, significantly reducing the likelihood of misoperation.

| Warehouse Area | Recommended Illuminance (lux) | Uniformity |

|---|---|---|

| General Storage | 100–200 | ≥0.4 |

| Sorting & Packing Area | 200–300 | ≥0.5 |

| Inspection / Quality Control | 300–500 | ≥0.6 |

| Cold Storage | 150–250 | ≥0.5 |

What are the best LED lights for warehouses?

From the perspective of practical application and long-term performance, LED high bay lights are the best type for warehouse lighting. The main reasons are their strong adaptability, wide range of applications, and ability to flexibly match different structural and operational needs. Whether it’s harsh industrial warehouse or large commercial retail warehouse, suitable wattage and light distribution methods can be selected to achieve soft and uniform lighting effects.

Depending on the layout or area, you can choose between round and linear designs, and they supports hanging, bracket, ceiling-mounted, and side-mounted, offering greater flexibility in installation and layout. From visual perspective, the high mounting position reduces glare, ensuring sufficient brightness while avoiding interference with vision.

More importantly, we have a very complete and scalable system of features. Our LED high bay lights can be configured with emergency power, dimming, color temperature adjustment, and motion sensing, allowing them to adapt to various changing situations without needing replacement later.

Can LED flood lights be used in warehouse?

Of course, outdoor warehouse LED lights typically use flood light types to illuminate doorways, loading and unloading areas, exterior walls, and surrounding pathways, which is crucial for ensuring safety and operational efficiency. Inside the warehouse, LED flood lights can also be used to supplement or enhance lighting. Mounted on walls or building structures, they can effectively illuminate specific areas and are suitable for irregularly shaped spaces. They offer greater flexibility in direction and coverage, can precise fill lighting and reducing dark areas.

What are the benefits of LED high bay lighting for commercial warehouses?

From energy-saving perspective, LED high bay lighting provide high brightness output while consuming relatively low wattage. In environments like commercial warehouses, where lighting is needed for long time and many fixtures are used, energy savings can lead to significant and sustained reductions in electricity costs. In terms of irradiate capabilities, they maintain stable and bright light coverage even at higher mounting heights. Protection and heat dissipation also meet industrial and commercial standards, featuring IP65 rating and die-cast aluminum heat sinks, lifespan over 50,000 hours and require no replacement or maintenance.

From lighting quality perspective, commercial warehouses experience frequent movement of personnel and goods. Bright, soft light can prevent visual fatigue and improve product identification, label reading, and overall work efficiency.

What are the steps for upgrade warehouse to LED lighting?

First, assess the existing warehouse lighting system, focusing on issues such as insufficient brightness, severe shadowing, frequent maintenance, or excessive energy consumption. This will help determine the necessity of an upgrade and the priorities for improvement. Then, consider whether features such as dimming, motion sensing, or emergency lighting are required.

The second step is to select suitable LED lights and determine the appropriate parameters to meet lighting standards. We recommend using professional lighting simulation software to determine this, as it will directly show the lighting effect.

Before the actual replacement, it’s necessary to check the existing voltage, wiring method, and installation structure to determine if direct replacement is possible, or if adjustments to the installation method and wiring are needed. This step is especially important for older warehouses and can effectively prevent rework during the installation phase. Once everything is confirmed, proceed with the LED installation.

If the warehouse is still in normal operation, it is recommended to upgrade the lighting in sections or batches to avoid complete shutdown. This allows the upgrade to be completed without disrupting daily operations. After installation, the brightness and functionality should be tested and debugging.

What are the costs of LED lighting for warehouses?

The purchase cost of LED lighting fixtures varies greatly, and both power and smart control features affect the unit price, which is typically the main and largest cost component. However, they offer lower energy consumption and longer lifespan, significantly reducing electricity bills and the frequency of fixture replacements. For warehouses with long operating hours, these cost savings are often even more pronounced in the long run. Choosing our high-efficiency LED high bay lights (190lm/W) can save 70-80% on energy costs compared to traditional lighting and 30-40% compared to other LEDs, while requiring no replacement or maintenance.

Overall, the true cost of LED warehouse lighting is only higher in the initial investment, but the long-term energy cost savings are substantial. This shortens the cost recovery period, making LED lighting sustainable long-term investment.

Can LED warehouse lights are connected to dimming system?

Absolutely. Modern LED warehouse lights are fully compatible with dimming systems, and the overall installation is not complicated. 0-10V dimming is simpler and less expensive, and is widely used in industrial lighting. DALI2 dimming is more precise, flexible, and smoother, but it is more costly. These are the two most commonly used methods, and we support either option. This allows for zoned, grouped, or batch adjustment of brightness in the warehouse, meeting the lighting needs of different work areas and usage periods, further saving energy and extending lifespan.

Get In Touch

We’re always excited about your message, so feel free to get in touch, we will reply you ASAP.