LED Industrial Lighting

Industrial lighting is crucial for safety and efficiency. It requires not only high brightness and energy efficiency but also the ability to withstand harsh environments, such as dust, water, and high temperature resistance. Our LED lighting series can provides stable lighting solutions for a variety of industrial environments.

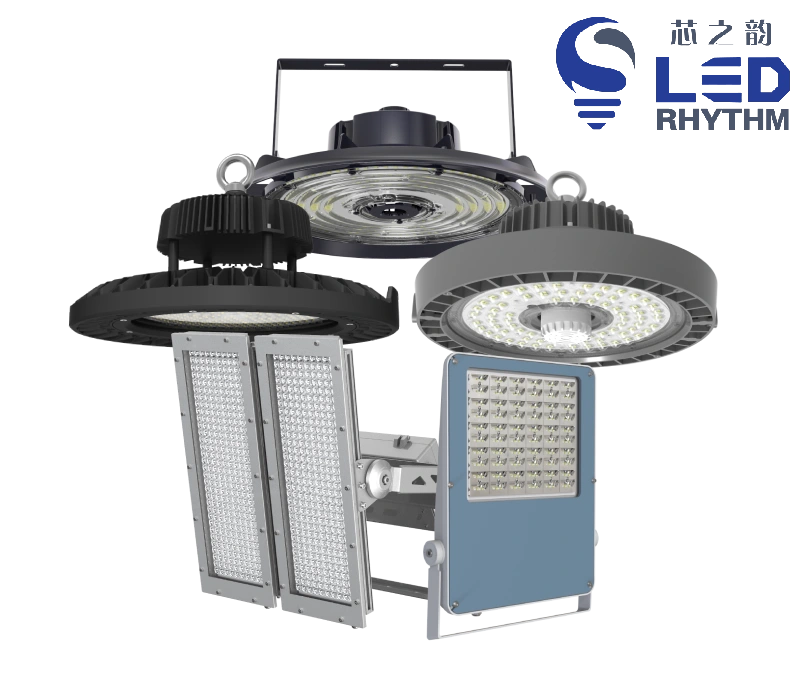

LEDRHYTHM - Fixture Types for Industrial LED Lighting

Industrial LED lighting is different from household lighting in that it must can provide stable illumination in large, harsh environments. Different types of fixtures are used depending on application. To ensure long-term, reliable operation, fixtures are typically more robust and heavier. Furthermore, they has higher power and luminous efficiency. Here are some common industrial LED lighting fixture series in LEDRHYTHM:

- LED high bay lights – Suitable for environments with ceilings over 6 meters, such as warehouses, factories and indoor sports.

- LED tri-proof lights – Excellent waterproof, dustproof, and corrosion-resistant features, most representative industrial LED lighting fixtures.

- LED flood lights – Provide uniform, large-area illumination, both indoors and outdoors.

- LED linear lights – Linear emitting surface, soft light, and excellent color rendering.

- LED high-temperature lights – Designed for areas with ambient temperatures exceeding 65°C.

- LED street lights – installed on high poles to provide safe lighting for industrial park roads.

Rapid Development of Industrial LED Lighting

As LED technology continues to mature, the industrial lighting sector is undergoing significant changes. Luminous efficacy has increased from the early 100 lm/W to over 150–180 lm/W, and product advantages in energy saving, lifespan, and optical design are becoming increasingly evident. Simultaneously, modern industrial LED lighting is becoming increasingly intelligent, with batch intelligent control, dimming, and sensors becoming increasingly common. Furthermore, lights are becoming increasingly capable of withstanding high and low temperatures, corrosive environments, and explosive atmospheres. This has completely transformed traditional lighting methods.

If you want to learn more about the latest trends, you can read our special article – “What is New in Industrial LED Lighting in 2025“

Why Choose LEDRHYTHM Industrial LED Lighting

High Efficacy and Energy Savings

Our LED series boasts a luminous efficacy of up to 190 lm/W, saving over 80% energy compared to traditional metal halide or fluorescent lamps. This significantly reduces businesses’ electricity costs and carbon emissions.

Ensure Safety

Industrial sites often face challenges such as dust, moisture, oil mist and vibration. LEDRHYTHM products feature IP65–IP69K protection ratings and IK08–IK10 impact resistance, ensuring stable operation and reducing maintenance risks.

Adapting Extreme Environments

For high temp areas like foundries and glass factories, our high-temp series offers stable operation at temperatures between 65–75°C, and can be customized down to 110°C. We can also provide cold-resistant products as low as -50℃.

Optical Design

All LED luminaires undergo professional optical design and offer a variety of light distribution methods to suit varying industrial areas. They effectively reduce glare, shadows and dark areas, enhancing safety and comfort within work area.

Intelligent Control

Supports DALI and 0–10V dimming, and can be integrated with smart sensors or IoT systems to achieve zoned lighting, automatic sensing, and energy savings, helping businesses enter the era of smart lighting.

Certifications and Long Lifespan

LEDRHYTHM are certified by international standards, including CE, RoHS, UL, and DLC. They boast a lifespan of 50,000–100,000 hours, reducing replacement frequency and long-term maintenance costs.

Industrial LED Lighting Affects Safety And Efficiency

In industrial environments, dim or flickering fixtures can easily lead to operator errors and even workplace accidents. Therefore, an excellent lighting system is crucial. It goes beyond simply providing light and directly impacts worker safety and productivity. Even, bright lighting helps maintain focus, preventing discomfort and fatigue.

LEDRHYTHM – Industrial LED Lighting Manufacturer in China

Founded in 2014, LEDRHYTHM is a professional industrial LED lighting manufacturer in China, with a comprehensive R&D, production, and after-sales service system. We have decades of manufacturing experience in the LED sector and maintain strict product quality management. We ensure that every product we ship meets international industry standards.

At LEDRHYTHM, we’ve exported industrial LED lights to over 20 countries across Europe, America, and Southeast Asia, and maintain long-term relationships with numerous distributors and end customers. With extensive experience in diverse applications, we can customize lighting solutions for any industrial areas.

LEDRHYTHM - Typical Applications in Industrial Lighting

Warehouse Lighting

Warehouses are a common sight in industrial lighting, both for storing goods and in logistics centers. No shadows is essential for larger warehouses, requiring higher brightness and uniformity. For example, linear high-bay lighting is more suitable for shelves and aisles to ensure efficient picking and work.

Factory Lighting

Factory environments are more complex, encompassing diverse work areas such as assembly, processing and testing. These environments can be subject to humidity, dust, vibration and high temperatures. This requires high-quality lighting protection, along with high brightness and durability to ensure safe and efficient production.

Workshop Lighting

The complex workshop environment may include welding, assembly, and testing, often accompanied by metal dust. This has high demands for both localized lighting and overall uniformity. Linear luminaires are ideal for providing uniform illumination over large areas, enhancing both precision and comfort.

Port Lighting

Port and wharf lighting needs to cover large areas and withstand harsh conditions such as salt spray, humidity and strong winds. Long-range projection, corrosion resistance and a high rating of protection are key requirements. LEDRHYTHM has designed flood lights and high-mast lights specifically for port areas.

Barn Lighting

Barn lighting is widely used in agricultural storage and livestock farming. Compared to general industrial lighting, barn lighting emphasizes environmental resistance, low glare, and spectral design. LEDRHYTHM provides LED tri-proof lights and high bay lights to meet these requirements, ensuring natural light and energy efficiency.

Cold Storage Lighting

Cold storage temperatures often drop below -30°C, requiring luminaires to be cold-resistant, condensation-resistant, waterproof, and capable of cold-starting. LEDRHYTHM's solutions are tailored to meet these needs, ensuring instant startup and stable operation even in low temperatures.

What is the equivalent power of industrial LED lighting and traditional?

The high luminous efficacy of industrial LED lighting enables it to achieve the same or even higher brightness as traditional lamps at lower power. For example, a 100W LED high-bay light can typically replace a 250W–400W metal halide lamp; while a 200W LED can replace a 500W–800W traditional metal halide or HPS.

This equivalent replacement not only significantly reduces energy consumption, but also reduces the number of fixtures and lowers maintenance costs. When replacing LED, the equivalent power will vary depending on the luminous efficacy and illumination requirements.

| Required Luminous Flux | LEDRHYTHM Industrial LED (190 lm/W) | Traditional Metal Halide / HPS (≈70 lm/W) |

|---|---|---|

| ≈ 20,000 lm | 100 W LED | 250 W Traditional Lamp |

| ≈ 40,000 lm | 200 W LED | 500 W Traditional Lamp |

| ≈ 60,000 lm | 300 W LED | 750 W Traditional Lamp |

| ≈ 80,000 lm | 400 W LED | 1000 W Traditional Lamp |

What is the best color temperature for industrial lighting?

In most LED industrial lighting, the color temperature is generally between 4000-6500 K. If below 4000 K, the light will be dim and yellowish, which is not conducive to work environments that require concentration. Higher color temperatures, on the other hand, can help improve productivity and maintain focus.

- 4000K to 5000K: Neutral white light, suitable for industrial areas where visual comfort is important.

- 5000K to 6500K: Cool white light, closer to daylight, often used in high-precision areas, inspection areas, and spaces requiring high concentration.

How often do LED industrial lighting need cleaning or maintenance?

LED industrial lighting fixtures have a high degree of protection and robust structure, effectively protecting their internal components and requiring less frequent maintenance. In harsh environments, such as those with high dust, high humidity, and strong corrosive conditions, cleaning should be done every 3-6 months. Other environments can be cleaned every 6-12 months.

Get In Touch

We’re always excited about your message, so feel free to get in touch, we will reply you ASAP.