LED Warehouse Lighting

There are many types of warehouses. In order to ensure that lights can run for a long time, lighting needs to not only reduce energy consumption but also improve worker safety and efficiency. Our LED lighting series can handle complex warehouse environments, ensuring stable lighting.

Warehouse lighting is a crucial and common component of industrial lighting. It improves the efficiency of modern logistics and cargo storage. Traditional lamps are gradually being phased out, and modern LED technology has solved many of the problems that once plagued warehouse lighting, significantly reducing long-term operating costs while improving safety and work efficiency.

Pain Points of Warehouse Lighting

Warehouses, as key areas for logistics and production storage, feature large spaces, high shelves, and complex operations. They place higher demands on lighting. Otherwise, shadows and dark areas can affect safety and efficiency. In actual use, warehouse lighting often faces the following common difficulties:

- High Spaces

Ceilings are typically over 8–20 meters high. Higher installed lighting fixtures can easily cause dark areas and uneven illumination in areas below. - Dense Shelves, Severe Obstruction

Warehouse shelves are high and numerous, and their layout easily blocks light, especially in narrow hallway, where dark corners can easily appear, hindering workers’ picking and handling. - Multiple Operation Areas

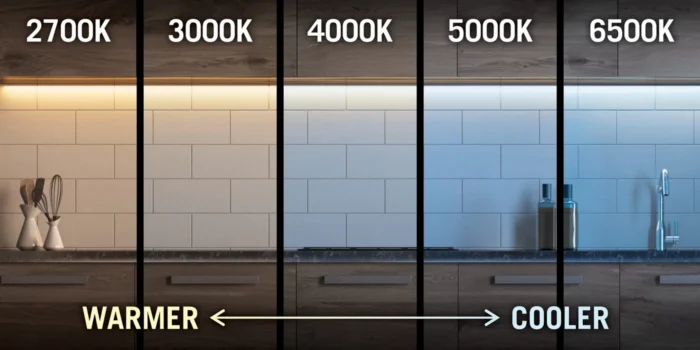

Warehouses not only have storage areas, but also packaging, sorting, and loading/unloading areas. Each area has different requirements for brightness and color temperature. - Complex Environments

Some specialized environments, such as those with high temperatures during the hot summer, as well as humidity and dust interference. These conditions also place certain requirements on the protective performance of warehouse lighting.

LEDRHYTHM - LED Warehouse Lighting Manufacturer in China

LEDRHYTHM has provided lighting replacement and new addition services to hundreds of warehouses around the world. As an LED industrial lighting manufacturer with more than ten years of experience, we can help our customers achieve more efficient, safer and more energy-efficient lighting solutions.

At LEDRHYTHM, first of all, lighting must be energy-efficient to the greatest extent possible. We achieve a luminous efficacy of 150-180lm/W for LED lights, consuming less electricity at the same brightness. Furthermore, our luminaires are rated for IP65/IP66/IP69K waterproofing and IK08/IK10 shock resistance. Also offer designs that can withstand both high and low temperatures, ensuring continuous and stable operation regardless of your warehouse environment.

LEDRHYTHM LED Lighting Fixtures For Warehouses

Because warehouses typically have high ceilings and large areas, LED high bay lights is the most suitable lighting. UFO LED high bays are suitable for illuminating wide areas, while linear LED high bays are ideal for shelves and aisles. Both provide bright and even lighting, avoiding shadows and dark corners. In LEDRHYTHM, their characteristics are:

- Can illuminate warehouse with 8-20 meter high ceilings, with high light efficacy and a wide range of power options.

- Available in a variety of narrow and wide beam angles to cover different areas of warehouse.

- Equipped with optical lens or PC diffuser to effectively reduce glare and improve workers’ eye comfort.

- 0-10V/DALI dimming as standard, and optional sensors and Zigbee systems can be used to achieve intelligent lighting.

- Installation method supports bracket type, side wall mount, ceiling or suspended to adapt to different warehouse structures.

LED vs Traditional Lamps in Warehouse Lighting

In the past, warehouse lighting used traditional fixtures including metal halide, HPS, or fluorescent lamps. These not only consumed a significant amount of electricity, but also required warm-up upon startup, had poor color rendering and required frequent maintenance. This reduced efficiency and resulted in high lighting costs.

In contrast, LED warehouse lighting overcomes all the shortcomings of traditional lamps and improves the quality and uniformity of light. LED can reduce energy consumption by 50-70%. Although the initial cost is higher, the long-term operating costs are greatly reduced.

| Feature | Traditional Lamps | LED Warehouse Lighting |

|---|---|---|

| Lifespan | 10,000–20,000 hours | 50,000–100,000 hours |

| Equivalent Wattage | 400W Metal Halide ≈ 150W LED | 150W LED replaces 400W MH |

| Protection Rating | IP20–IP40 | IP65–IP66 |

| Maintenance | Frequent replacement, high labor cost | Minimal maintenance |

What is the recommended illumination for warehouse lighting?

Illumination (lux) is an important indicator of lighting brightness. In warehouse lighting, illuminance affects visibility and comfort. Generally speaking, higher illuminance indicates brighter light, allowing for clearer visibility of shelves and product labels, significantly reducing the likelihood of misoperation.

| Warehouse Area | Recommended Illuminance (lux) | Uniformity |

|---|---|---|

| General Storage | 100–200 | ≥0.4 |

| Sorting & Packing Area | 200–300 | ≥0.5 |

| Inspection / Quality Control | 300–500 | ≥0.6 |

| Cold Storage | 150–250 | ≥0.5 |

Other Blogs

Get In Touch

We’re always excited about your message, so feel free to get in touch, we will reply you ASAP.