Table of Contents

Toggle1. Introduction

Industrial LED lighting has undergone revolutionary development in the past decade and has basically replaced traditional fluorescent lights and halogen lights. There are many types of industrial led lights nowadays. It is necessary to choose right lights for different scenarios, so it is extremely important to understand their latest technologies and development trends.

2. High-Temperature LED Lights

With global warming and increasingly developed industries, lights that can withstand high temperature environments have become a trend. For example, industrial LED lights that operate stably in foundries, metallurgical plants, and glass factories workshop and warehouse need to break through the thermal failure bottleneck of traditional LEDs (light decay, color deviation, and life reduction), and also have the characteristics of different LED lights types (flood lights, high bay). Its core technology revolves around three dimensions: heat dissipation design, material upgrades, and intelligent control, and combines emerging technologies to achieve reliable operation.

2.1 Technological Breakthrough

- The radiator is made of high thermal conductivity aluminum or copper, with a fin structure design.

- Divided into regions for independent heat dissipation, the lamp body and power supply are separated to avoid heat source superposition.

- COB integrated packaging: reduce the risk of solder joint failure and resist mechanical vibration (the impact test in the foundry workshop passed 10G acceleration).

- Use high temperature resistant components: such as 105℃ resistant electrolytic capacitors and silicone encapsulated LED chips.

- No electrolytic capacitor design: eliminate the risk of electrolyte drying up at high temperatures (lifespan from 5,000 hours → 100,000 hours).

- The driver has a temperature control protection circuit, which can automatically reduce power at high temperatures, greatly improving the longevity of LED light.

| Specification | High-Temperature LED Fixture | Traditional Industrial LED (Non-Optimized) |

|---|---|---|

| Operating Temperature | -40℃ to +75℃ | -30℃ to +40℃ |

| Lifespan at 75℃ | >50,000 hours | <20,000 hours (30% lumen depreciation) |

| Lumen Maintenance | 90% @10,000 hours | 60% @10,000 hours |

| Vibration Resistance | IK10 (20 Joule impact) | IK08 (5 Joule impact) |

| Corrosion Resistance | Pass ISO 9227 Salt Spray Test 1000h | Rust appears within 500h |

2.2 Application Scenario

High temperature factories, steel mills, drying rooms (75℃+high humidity), smelting workshops (75℃+metal dust), glass kilns (75℃+strong radiant heat).

Outdoor construction sites in hot climates such as the Middle East and Africa.

Finally, let me recommend our company’s high-temperature products, including high-temperature high-bay lights, high-temperature floodlights, and high-temperature tri-proof lights. There is always a solution that suits you.

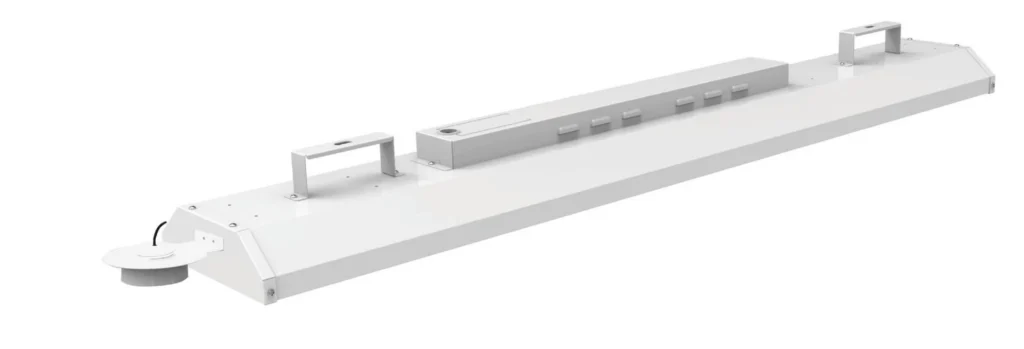

3. High Bay LED Lights

Today, core technology of new industrial high-bay LED lights (usually refers to lighting large spaces such as warehouses, factories, gymnasiums, etc. installation height of 6-30 meters) has shifted from the simple pursuit of light efficiency to the integration of lighting quality, intelligence and the entire life cycle.

3.1 Technological Breakthrough

- Higher light efficiency (>150lm/W) ensures long-term operation of workshops and warehouses and more energy-saving

- Adjustable beam angle design: By rotating the optical module, it can achieve stepless adjustment from 15° (high-density storage area) to 120° (channel area), replacing traditional multi-model lamps.

- Using asymmetric lenses/reflectors, the light is accurately projected onto the working plane (rather than the ceiling or aisle), the vertical illumination is increased by 40%, and the shelf shadows are eliminated (such as the illumination uniformity of a 50-meter shelf channel>0.8).

- Driving power supply: independent heat dissipation, physically isolated from the light source, to avoid mutual thermal interference.

- Millimeter wave radar + light sensor: detection accuracy reaches 0.1m (traditional infrared is only 3-5m), realizing human/vehicle/forklift motion trajectory tracking lighting.

| Parameter | Mainstream in 2023 | Benchmark in 2025 | Improvement Rate |

|---|---|---|---|

| Luminous Efficacy | 130–140 lm/W | 150–160 lm/W | +15% |

| Lifespan | 50,000 hours | 100,000 hours | +100% |

| Smart Integration Rate | 30% (basic sensors only) | 80% (full-function AIoT) | +167% |

| Installation Efficiency | 15 min/unit | 3 min/unit | +400% |

| Vertical Illuminance Uniformity | 0.6–0.7 | >0.85 | +25% |

3.2 Application Scenario

Warehouses, factories, gymnasiums, logistics centers (8~25 meters high sheds), etc., according to different heights, the higher the height, the smaller the beam angle and the greater the power should be.

4. LED Flood Lights

Industrial floodlights are the “all-round warriors” in industrial lighting. They are used in the most scenarios and are designed for large-scale, high-uniformity lighting. Their technological evolution is shifting from simple high brightness to intelligent light control, extreme environment adaptation, and deep integration of energy efficiency and safety.

4.1 Technological Breakthrough

- The free-form prism lens is used to precisely control the beam angle within 15°~120° (traditionally fixed at 60° or 90°), with a uniformity of >0.8, eliminating the problem of “overexposure at the center and dim at the edge”.

- Asymmetric light distribution design: achieves 70° tilted light projection on one side (such as port quayside bridge lighting, reducing light pollution to the sea surface).

- Multi-channel partition control: 4-6 independent light-emitting zones are divided in a single lamp, which can be switched/dimmed in different zones (only illuminate the areas in need, saving 30% energy).

- IP66/IP69K housing: die-cast aluminum housing + chemical nickel plating, resistant to salt spray corrosion (standard 4000 hours).

- Modular design, a floodlight can be divided into 2-8 separate lights bodies to achieve wider lighting at different angles.

| Parameter | Traditional Flood Light (2020) | High-End Industrial Flood Light (2025) | Improvement |

|---|---|---|---|

| Luminous Efficacy | 100–110 lm/W | 150–160 lm/W | +50% |

| Ingress Protection Rating | IP65 | IP66 / IP69K Dual Certification | Resistant to high-pressure washdown |

| Smart Response Time | 1–2 seconds | <0.2 seconds | Seamless forklift detection |

| Extreme Temperature Range | -20℃ to 50℃ | -40℃ to 85℃ | Covers arctic to desert environments |

| Explosion-Proof Rating | None | Ex d IIC T6 | Enhanced safety redundancy |

4.2 Application Scenario

Construction sites, parking lots, stadiums, factory walls, building exteriors, equipment lighting. Whether it is salt spray corrosion, strong wind vibration, ship crane obstruction, or voltage instability, dust blockage, low temperature cold start. Our new industrial led floodlight series can give you the best solution.

5. Industrial LED Tri-Proof Lights

Tri-proof lights (waterproof, dustproof, and anti-corrosion) are the ultimate line of defense in industrial LED lighting. The new in industrial Tri-proof is a deep integration of materials, sealing, and intelligent protection. It is truly suitable for all kinds of extreme environments.

5.1 Technological Breakthrough

- Sapphire glass lens: Mohs hardness 9 (no scratches from sand and dust impact), light transmittance >95% (10-year attenuation <3%).

- Built-in heat pipe directs heat to the edge of the shell, and the shell temperature uniformity is >90% (eliminating seal aging caused by local hot spots).

- Molecular-level sealing technology achieves IP66/IP69K/IK10 protection, which is truly dustproof, waterproof, anti-corrosion and shockproof.

- Integrated molding, designed in a variety of lengths, can be used in small harsh spaces or closed garage lighting.

- Adopting thin-film capacitors + GaN switching devices, the life span is >100,000 hours (no explosion risk in high temperature and high humidity environments).

| Parameter | Traditional Tri-Proof Light | Industrial-Grade Tri-Proof Light (2025) | Improvement |

|---|---|---|---|

| Protection Rating | IP65 | IP69K + IK10 | Resists 200℃ high-pressure washdown |

| Corrosion Resistance Lifespan | 3–5 years | >15 years | +300% |

| Light Transmission Retention | 70% @ 5 years | >92% @ 10 years | +31% |

| Explosion-Proof Rating | None / Ex dm IIB | Ex db IIC T6 | Covers hydrogen environments |

| Extreme Temperature Range | -20℃ to 45℃ | -50℃ to 75℃ | Covers cryogenic to steam zones |

5.2 Application Scenario

Basements, food processing workshops (high humidity sterilization areas), chemical and pharmaceutical plants (strong corrosion areas), ports and offshore platforms (salt spray severe corrosion areas), mines and tunnels (high dust areas), wind power generation interiors, etc.

6. Summarize

The new industrial LED lighting system in 2025 is composed of these four core categories. They are like the “four-dimensional pillars” of the industrial light environment, respectively overcoming the challenges of different extreme environments.

Therefore, choosing a professional lighting manufacturer can save long-term costs and improve industrial efficiency. If you need, you can also view our company profile and all products.

7. People also ask

Which is your best LED lights for workshop?

The workshop generally has a high ceiling and a high temperature, and sufficient brightness ensures that workers can work smoothly. And minimize the number of maintenance times, so choosing our high temperature high bay lights is the most appropriate.

Which is your best led garage lighting?

Garages are usually enclosed spaces in basements, which are humid and have other factors. In addition, the space is large, so lamps with uniform and soft light are needed. Long life and low maintenance are also very important. Our vapor tight fixture light series can meet these requirements.

Which is your best led lights for warehouse?

Warehouses are generally used to store goods and require lamps that can adapt to large temperature differences. They also have high ceilings and large spaces. We always a high bay lights series that can suit you.

How long do industrial LED lights last?

The lifespan of industrial LED lights far exceeds that of traditional lighting, with a theoretical lifespan of more than 100,000 hours (>11 years for 24-hour operation), but the actual lifespan depends on:

- Technical level (core technologies such as no electrolytic capacitors/ceramic substrates)

- Environmental severity (temperature/corrosion/vibration triple dimensions)

- Optical devices (PC lens (yellowing in 5 years) vs. glass/sapphire lens (light transmittance >92% in 10 years))

High-end products have achieved “lifespan exceeding equipment replacement cycles”

What is the development trend of industrial LED lighting?

Industrial LED is indeed undergoing three major transitions: first, intelligence, where lamps are transformed from light emitters to data nodes; second, reliability, where the life span in extreme environments exceeds 100,000 hours; and finally, sustainability, a green revolution from materials to energy.

In the future, it will also develop towards comprehensive intelligence, integrated light storage and charging, extreme environmental adaptability, comprehensive greening, personnel experience, and longer life span.