An LED high bay light with adjustable power and color temperature

In actual demand, in order to adapt the high bay light to different application scenarios, customers usually buy a variety of specifications of high bay light to correspond to different working scenarios, so that the working scene matches the color temperature power of the high bay light, so according to the work needs, When customers deal with different color temperature powers required by different working environments, they use high bay lamps that are constantly replaced and installed, which is particularly troublesome, and increases the number of lamps and costs customers buy each time. Although this method stimulates consumption and increases sales, it reduces the utilization rate of high bay lamps.

And the driving power of the current high bay light is close to the radiator of the lamp body, so that a large part of the heat of the LED is transferred to the driving power, causing the temperature of the driving power to rise and greatly reducing the life of the driving power. On the contrary, the temperature of the driving power will also be transmitted to the LED, and the two will affect each other, thereby reducing the life of the entire lamp. Therefore, it is necessary to design a method that can adjust different color temperatures on a high bay lamp by improving the utilization rate of the radiator.

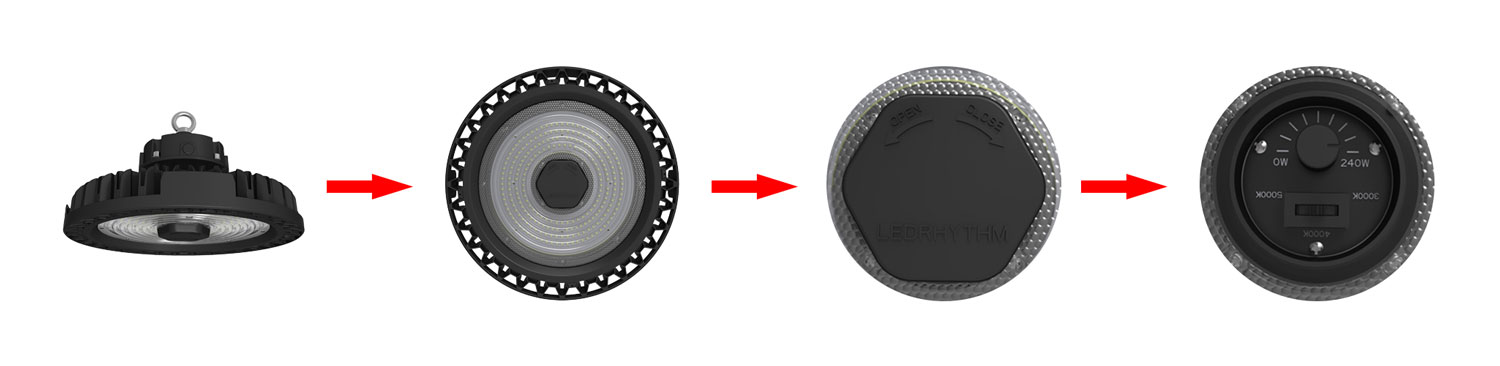

The Diamond II series launched by Ledrhythm adopts the method of setting the color temperature power adjustment switch and using the radiator to isolate the driving power supply from the housing, and designs an LED high bay light that can adjust the color temperature according to actual needs and can dissipate heat thoroughly, which solves the problem of existing The problem of insufficient heat dissipation of the LED high bay light and the inability to achieve color temperature adjustment.

Diamond II adopts the method of setting the color temperature power adjustment switch and using the radiator to isolate the driving power supply from the housing, and designs an LED high bay light that can adjust the color temperature according to actual needs and can dissipate heat thoroughly, which solves the problem of the existing LED high bay. The problem of insufficient heat dissipation of the lamp and the inability to achieve color temperature adjustment.

The conversion of three color temperatures can be realized according to actual needs (3000k, 4000k, 5000k three color temperatures can be switched at will). Since the power and color temperature of lamps can be adjusted, the stocking specifications of the engineering company can be reduced, so that one specification can cover multiple applications and realize quick response to customer needs, and it is more convenient to adjust the power by bidirectional rotation. The scale mark makes the power adjustment more accurate, more efficient, and more energy-saving, and adjusts to the most suitable power according to the on-site illumination requirements, so as to achieve the purpose of energy saving and emission reduction.

Widely used in industrial production, warehousing, indoor sports, etc.