Table of Contents

ToggleIntroduction

Lighting in high temperature industrial environments not only needs to withstand extreme ambient temperatures, but also must consider the impact of large amounts of dust and steam generated in these work areas on light. LEDRHYTHM offers ultra-low color temperature 1800–2200K (amber to candlelight), which provides enhanced penetration, reduced blue light scattering, and a softer visual experience in high-temperature and particulate-laden air.

This article will detail the advantages of ultra-low color temperature lighting in high temperature work areas such as steel mills and metallurgical workshops.

Review of Color Temperature (CCT)

Color temperature of industrial LED lighting is usually between 3000K and 6500K, which means that visual perception is from warm write light to daylight. You can view more articles about warm white light to daylight.

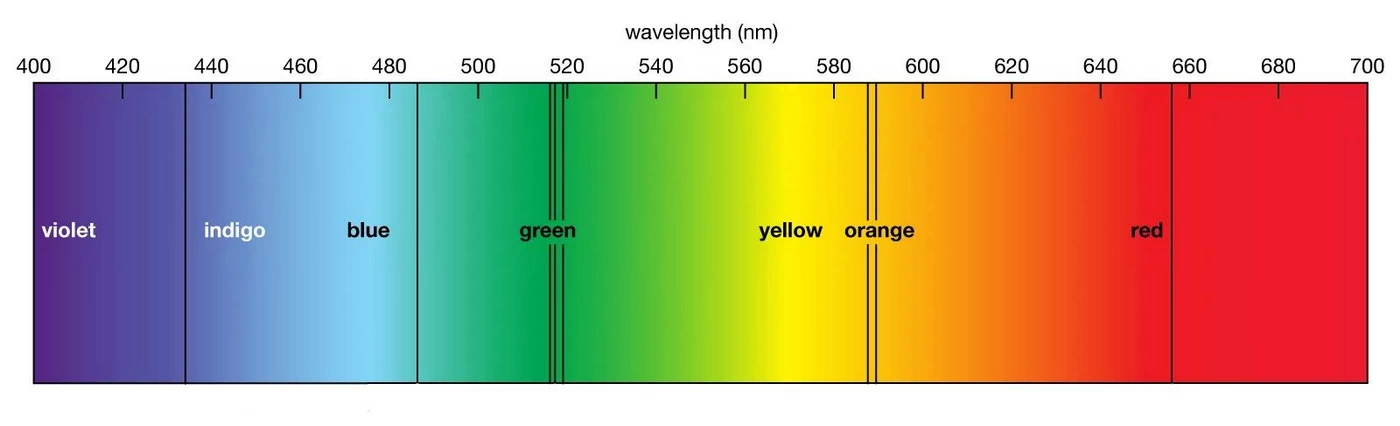

Before discussing ultra-low color temperatures of 1800K/2200K, it’s important to reconsider the relationship between correlated color temperature (CCT) and light spectrum. High (5000K), the blue wavelengths (380-480nm) in spectrum for higher proportion, resulting in clear and sharp visual experience; Low (3000K), the red and yellow (580-730nm) in spectrum for higher proportion, resulting in softer, warmer visual. So the lower 1800K/2200K will have higher proportion of red and yellow light than 3000K. View more about visible light and wavelengths.

This change in spectral wavelength of directly determines the propagation characteristics of light in medium. In high-temperature air containing dust, smoke, and moisture, short-wavelength light is easily scattered by particles, while long-wavelength light can penetrate more effectively. This is physical basis for why low color temperature light has higher visibility in complex atmospheric environments.

| CCT | Red Yellow Light Proportion | Penetration Power | Notes |

|---|---|---|---|

| 1800K | ≈ 80% | High | Dominated by long-wave red/orange energy — strongest penetration and minimal short-wave scattering. |

| 2200K | ≈ 65% | High–Medium | Amber balance — very good penetration with slightly more mid-wave content than 1800K; good compromise for visibility and color rendering. |

| 3000K | ≈ 45% | Medium | Warm white with balanced spectrum; reasonable general visibility but increased short-wave scattering versus amber. |

| 5000K | ≈ 20–25% | Low | Cool white with high blue content — prone to strong scattering in particulate/steam environments and greater perceived glare. |

Note: The percentages listed here are approximate estimates. Actual values depend on each LED’s SPD — use measured SPD data for precise engineering decisions.

Why Choose 1800K–2200K Low CCT?

In high temperature industrial workplaces, such as steelmaking furnaces, casting lines, and metallurgical workshops, the air is often filled with hot air currents, smoke, steam, and light reflected from metal. These factors can cause complex interference with light propagation and human perception, and color temperature is precisely the most sensitive, yet easily overlooked, factor among these.

For example, common examples in our lives:

- Nighttime road lighting: low color-temperature, yellowish light offers better visibility and safer driving than white light.

- Tunnel exit lighting: Warm yellow light can significantly reduce the contrast between light and dark (white hole effect) experienced by drivers exiting tunnel.

High color temperature, high-bay LED lights (4000K–6000K) with higher proportion of blue light exhibit extremely strong scattering effects in high temperature metallurgical workshop. Short wavelength radiation in blue light band is easily scattered at smoke and dust particles, creating visual “white fog” or “reflective curtain.” This makes it difficult for workers to clearly see surface contours or metal edges, even in areas with sufficient illumination.

Therefore, LEDRHYTHM has achieved high temperature LED lights with ultra-low color temperatures of 1800K–2200K, and strongly recommends their use in harsh high temp factory environments. This is based on a combined assessment of optical, visual physiology, and engineering practices.

- Exceptionally strong penetrating power, have high visibility even in air conditions containing iron shavings, steam and dust particles.

- 1800-2200K has low proportion of blue light, which weakens short-wavelength reflected energy. Reduces glare and specular reflections on metal surfaces.

- The light color is close to natural twilight/candlelight, with negligible suppression of melatonin, making it more conducive to physiological recovery.

- LEDRHYTHM high temp LED lighting achieves 1800K-2200K while also ensuring high color rendering and high luminous efficiency.

In high-temperature working areas, complex brightness contrasts and chaotic reflections cause the visual system to frequently switch between photopic and mesopic vision. In these conditions, the excessive blue light in high color temperatures can cause frequent pupil constriction, resulting in “visual strain.”

LEDRHYTHM - High Temp LED Lights vs HPS for 1800-2200K

High-pressure sodium lamps (HPS) were once the mainstream “low color temperature light source.” They are commonly found in steel mills, docks, and tunnels, with deep amber light color of 1900–2200K. HPS have dense, highly penetrating warm light and perform well in high-temperature, high-steam, and dusty factories. For LED lighting to achieve 1800K, it must sacrifice high color rendering and high luminous efficacy.

However, at LEDRHYTHM, we’ve achieved the same low color temperature as HPS in high temperature LED lights, while ensuring that color rendering and luminous efficacy do not decrease significantly. Our comparison is not to prove “which is brighter or better,” but to answer a more important question — how can LED lighting maintain visual comfort and penetrating power of 1800–2200K, while achieving color rendering, efficacy, and stability required by modern lighting.

| Item | HPS | LEDRHYTHM High Temp LED |

|---|---|---|

| Color Temperature | 1800–2200K (Fixed) | 1800–2200K (Optional) |

| Color Rendering Index (CRI) | 20–30 | ≥60 |

| Luminous Efficacy | 70–90 lm/W | 130–160 lm/W |

| Light Penetration | Excellent (Strong Amber Component) | Excellent (Balanced Spectrum Control) |

| Energy Efficiency | Low | High |

| Start Time | 30–60 seconds | Instant (≤0.5s) |

| Heat Resistance | Medium | Up to 75°C ambient |

| Lifespan | 10,000–15,000 hrs | 50,000+ hrs |

| Maintenance Cost | High | Low |

Recommended LEDRHYTHM High Temp LED Lights

In practical industrial high temperature lighting applications, the heat resistance and stability of LED lights are also very important. We offer high temp high bay LED lights that can withstand ambient temperatures of 65℃, 75℃, and customizable up to 110℃, optional high-penetrating of 1800K-2200K, as highlighted in this article. Additionally, we also offer vapor tight and floodlight type fixture with heat resistance of 65℃-75℃; please view complete series.

Conclusion

Lower the color temperature (1800-2200K), the less blue light (short wavelength) percentage and the more red and yellow light (long wavelength). In environments with high dust and steam, the lighting penetration will be stronger.

LEDRHYTHM is not about pursuing lower color temperature numbers, but about exploring the perfect balance of light in extremely high temperature environments. We retains the penetration of warm light while maintaining the high efficiency and stability of LED.

FAQ

Is it difficult to convert HPS into 1800K LED high temperature lights in metallurgical workshop?

In reality, HPS retrofitting in high temperature factories is not as complicated as people imagine. After selecting a suitable LED manufacturer and fixtures, you only need to consider voltage and installation compatibility. LEDRHYTHM supports a wide voltage input of 100–277V, so there is no need to replace the main line or rewire. As for installation, we support suspender mounting at various heights and U-shaped adjustable brackets, facilitating direct replacement at existing HPS installation locations.

What is the biggest impact of achieving low CCT of 1800-2200K on LED lighting?

Because the 1800-2200K orange-red wavelength range has higher proportion, the color rendering index (CRI) in LED lighting is usually lower. However, it is still between 60 and 70, which is better than HPS (20-30). Secondly, these longer wavelengths of light (red-orange) usually require more energy to convert, which makes the luminous efficacy of low color temperature LED slightly lower. Finally, the visual clarity and contrast are not as good as high color temperatures, making them unsuitable for use in precision work areas.

Will high temp high bay LED lights at 1800K/2200K affect their protective properties?

While low color temperature lighting requires consideration of spectral output during design, it does not compromise the fixture protection. As long as the LED lights materials, design, and testing meet standards, its ability to withstand harsh environments will not be diminished. LEDRHYTHM offers IP65+ protection and excellent heat dissipation, unaffected by CCT between 1800-2200K.