Table of Contents

ToggleIntroduction

LED high bay lights are the most typical and commonly used type of indoor industrial lighting, and are almost indispensable for LED warehouse lighting application. Appropriate brightness or lumen output is crucial for improving picking efficiency, forklift safety, employee focus, and energy costs. Many people are unsure how bright the high bay LED lights should be, facing the varying lighting needs of warehouse different areas, different ceiling heights, and different beam angles of the luminaires. This article will discuss in depth.

Prioritize Lumens Over Wattage

Lumens are the unit of luminous flux, and they are the true indicator of brightness. The higher the total lumen output, the brighter the luminaire will be. Watts, on the other hand, are measure of power consumption; the higher the wattage, the higher the power consumption. The key factor is luminous efficacy, which represents the luminous flux emitted per watt of fixture. This explains why, even with the same 150W LED high bay light, some have mediocre lighting effects, while others can be installed in warehouse 12 meters or even higher, still keeping the ground clearly bright.

Currently, the efficacy of LED high bay lights on the market varies greatly, ranging from 120 lm/W, 150 lm/W to 170–190 lm/W. If you only look at the wattage and not the luminous efficacy, you can easily buy a light fixture that consumes a lot of power but is not bright enough. For example, 200W lights with efficiency of 120lm/W is not as bright as 150W with 190lm/W.

- 150W * 120 lm/W = 18,000lm

- 200W * 120 lm/W = 24,000lm

- 150W * 150 lm/W = 22,500lm

- 150W * 190 lm/W = 28,500lm

At the same power, high efficiency LED high bay lights can output 40%–60% more brightness, which will directly affect the illuminance, visual clarity and energy cost of warehouse lighting. Therefore, when considering the brightness of lighting fixtures, we must change our old way of thinking. Instead of judging whether fixture is bright enough by its wattage, prioritize lumens and then combine this with luminous efficacy to choose a more energy-efficient yet brighter solution. This will help you save on electricity costs in the long run.

Right Illuminance in Warehouse Lighting

Before determining how many lumens each light fixture in the warehouse lighting, it is necessary to first determine the required illuminance for each area inside. Then, we can select suitable light fixtures based on different installation heights, luminous efficacy, and beam angles. Dimmable LED high bay lights are recommended, as they can be adjusted for dimming conditions. View detailed information about lux, lumens, and watts.

- 100–200 lux: Warehouse overall lighting. Not too bright; just enough to ensure clear visibility of the floor and goods, and even, smooth.

- 200–300 lux: Suitable for work areas. Higher brightness ensures details, labels, etc., are clearly visible, reducing error rates and improving efficiency.

- 300 lux+: Brighter and more focused vision, more suitable for precision work areas, data processing areas, etc., but be careful to avoid glare.

| Warehouse Area | Main Function | Illuminance | Notes |

|---|---|---|---|

| Loading Dock | Loading, vehicle movement | 200 – 300 | Safety first, uniform brightness |

| Main Storage Area | Storage and locating goods | 100 – 200 | Horizontal and vertical lighting |

| Narrow Aisles / Dense Racks | High-rack picking | 150 – 200 | High uniformity, precise operation |

| Picking / Packing Zone | Sorting, checking, packing | 200 – 300 | Bright task lighting |

| Internal Main Aisles | Movement | 150 – 200 | Provide clear guidance |

| Warehouse Office | Office and data work | 300 – 500 | Comfort lighting, glare control |

The table can be used as a reference; it represents our experience. If you are unsure about the illuminance level for your warehouse, you can refer to internationally accepted lighting design standards, such as IES (Illuminating Engineering Society of North America) and CIBSE (Illuminating Engineering Society of the United Kingdom). These standards provide established lighting ranges for various storage areas, shelving areas, and work areas. For older warehouses without lighting drawings, this is a very reliable reference.

Different Ceiling Heights

After determining the required illuminance for each area of the warehouse, the next step is to estimate the actual luminous flux (Lumens) that each LED high bay light should possess based on the ceiling height. The reason is simple: the farther the light fixture is from the ground, the more significant the light attenuation. To maintain the same illuminance at the ground, higher brightness fixtures must be used. Therefore, there is a very direct correlation between height and lumens.

- 6-8 meters (20-26 ft): 10,000-20,000 lumens is sufficient

- 8-12 meters (26-40 ft): 30,000-40,000 lumens

- Over 12 meters (40 ft+): 40,000-60,000 lumens

| Mounting Height | 100 lux | 200 lux | 300 lux | 400 lux |

|---|---|---|---|---|

| 6-8 m | 6,000 – 10,000 lm | 10,000 – 16,000 lm | 16,000 – 22,000 lm | 22,000 – 28,000 lm |

| 9-12 m | 10,000 – 16,000 lm | 16,000 – 26,000 lm | 26,000 – 34,000 lm | 34,000 – 42,000 lm |

| 12-15 m | 16,000 – 26,000 lm | 26,000 – 36,000 lm | 36,000 – 48,000 lm | 48,000 – 60,000 lm |

| 15 m+ | 26,000 – 38,000 lm | 38,000 – 52,000 lm | 52,000 – 68,000 lm | 68,000 – 80,000 lm |

It’s worth noting that even with very high warehouse ceilings, it doesn’t necessarily mean extremely high-powered or ultra-bright LED high bay lights are required. Many projects utilize extra-long suspension chains or wires to lower the fixtures to more reasonable installation height. This allows achieving the target illuminance with lower wattage and lower lumens, reducing overall costs.

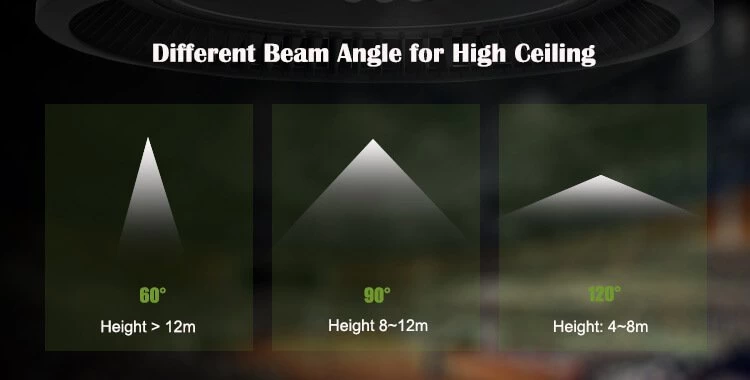

Different Beam Angles

Narrow beam angle concentrates light in a smaller area, significantly increasing ground illumination, but reducing the coverage area; wide beam angle distributes light more widely, but reduces the average ground illuminance. Therefore, LED high-bay light with the same lumen output might be too bright with 60° beam angle, but insufficient with 120° beam angle. This is the root cause of many customers’ misconception that the luminous flux is insufficient.

So, while keeping the installation height and fixture lumen output constant, different beam angles can achieve different illuminance levels. However, the beam angle cannot be chosen arbitrarily. Warehouse heights vary greatly, commonly ranging from 6m to 15m+, so the beam angle should be matched to the installation height as closely as possible.

- Narrow beam angle (45°) should never be used at low installation such as 6–8m, otherwise it will cause severe glare and uneven lighting;

- Wide beam angle (120°) should also not be used at installation of 12-15m+, otherwise the brightness will be severely insufficient.

However, different beam angles can still be selected to redefine the brightness of LED high bay lights. For example, achieving 200 lx in a warehouse with installation height of 6-8 meters:

- 120° beam angle: 12000-20000 lumens

- 90° beam angle: 10000-16000 lumens

Achieving 200 lx in a warehouse with installation height of 9-12 meters:

- 90° beam angle: 18000-28000 lumens

- 60° beam angle: 15000-22000 lumens

Choose LEDRHYTHM LED High Bay Lights for Warehouse

After detailed analysis of factors such as brightness, luminous efficiency, beam angle, and installation height, you can now more clearly estimate how bright and how many lumens of LED high bay lights your warehouse needs. LEDRHYTHM can meet your brightness needs while reducing wattage with high luminous efficiency, thus saving you more energy.

We offer two types of professional LED high bay lights: UFO and linear, covering multiple beam angles of 120°, 100°, 90°, 60°, and 45° to meet your lighting needs for warehouses with heights of 6-15 meters+. Efficiency can reach up to 190 lm/W, helping you achieve higher brightness with lower energy consumption.

More importantly, LEDRHYTHM doesn’t just sell LED lights; we also provide complete warehouse lighting solutions. We’ll customize lighting designs free for you, ensuring optimal illumination and the lowest cost.

- Recommend the appropriate beam angle based on your warehouse height and structure.

- Calculate the required luminous flux for each luminaire based on functional area illuminance standards.

- Design the optimal luminaire layout based on aisle direction, shelf height, and density.

- Select the most suitable luminous efficacy level based on your budget and energy-saving goals.

- Support multiple intelligent control methods: sensor, dimming, wired, and wireless systems.

People Also Ask

Why are dimmable LED high bay lights recommended for warehouses?

In the initial design, select LED high bay lights brightness that can meet the highest possible illuminance requirements, and they must be equipped with dimming systems; when the warehouse illuminance requirements change, they can be dimmed or brightened at any time, and power consumption will be adjusted accordingly, which will provide more flexible control over the brightness.

In contrast, if insufficient illumination is discovered later, non-adjustable high-bay lights can only be addressed by replacing the fixtures or increasing their quantity, which is costly and complex to implement. However, if the initial brightness is too high and cannot be dimmed, this will increase operating electricity costs and affect visual comfort.

Does a higher warehouse require brighter LED high bay lights?

Not necessarily. In warehouse lighting with higher ceilings, there are two common methods to achieve the target ground illuminance without increasing the brightness of individual fixture.

- First, choose professionally designed narrow-beam LED high-bay lights, such as 60°, 45°. These concentrate the light, reducing light diffusion and waste in the air, allowing more effective light to fall on the ground or work surface, thus illuminance will not decrease while the lumen output remains unchanged.

- The second is to use an extended suspension method to lower the actual installation height. This is unaffected by the actual ceiling height of the warehouse and still meets the lighting requirements.

However, if the number of lamps is limited, preventing an increase in lamp density, or if the shelves or goods are very tall, choosing higher-lumen, brighter lamps is the best option.

Would using very bright LED high bay lights in warehouse consume a lot of electricity?

Not necessarily. The power consumption is affected by the wattage of the light fixture, not its brightness. Even a brighter light may consume less energy than a lower-brightness light because of its luminous efficiency. For example, we can achieve efficiency of 190 lm/W, which, while maintaining the same brightness, saves 30% more energy than other LED high-bay lights and over 70% more energy than traditional lighting fixtures. Therefore, when choosing light fixture, if energy efficiency is a priority, you should pay more attention to its luminous efficiency. High efficiency ensures higher brightness output while saving energy.