Table of Contents

ToggleIntroductions

A vital component of personalizing contemporary lighting arrangements is cutting LED strip lights. Any project gains flexibility when you can cut LED lights to fit your space, whether you’re using Daybetter LED lights, 110V strip lights, or sophisticated addressable LEDs.

All of your queries will be addressed in this handbook, including:

- Are LED strips safe to cut?

- Can you cut LED strips?

- Where can I safely cut LED strips?

- How can common problems like shorts or broken LED pads be avoided?

See our Who Invented the Lightbulb and Light Bulb Shapes & Sizes articles for additional information on the fundamentals of lighting.

Can you cut led strip light?

As long as you adhere to the manufacturer’s instructions, you may cut the majority of LED strip lights, including Daybetter LED lights and GE Cync smart LED strips. Strips must frequently be cut in order to fit into precise shapes or areas.

The cut line should always be the location where LED strips are cut. This guarantees that the strip will continue to work after trimming. For accuracy, the majority of strips, including addressable LEDs, have predefined cut lines.

How to Correctly and Safely Cut LED Strip Lights

Cutting LED light strips yourself is a completely feasible and safe DIY operation. As long as you find the correct cutting point, confirm that it is low-voltage light strip, and properly handle the fracture after cutting, you can enjoy fun of customizing lighting lengths!

Equipment Needed to Cut LED Strips

You’ll need the following to guarantee a safe and clean cut:

- Sharp scissors or a power tool.

- Or use a sharp utility knife to cut vertically along shear point.

- For reconnection, use the LED light connector plug and accompanying soldering tools.

Where To Cut LED Strip Light

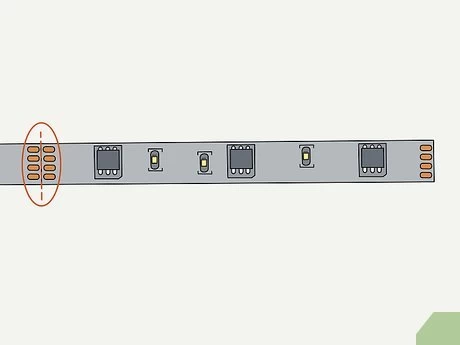

The light strip usually has clearly marked cut line, commonly marked by copper pads or dashed lines. Cutting outside these lines can harm the circuit.

At the desired cutting point, ensure the scissors or blade are perpendicular to the light strip.Cut quickly and cleanly, keeping the cut as smooth as possible.

Processing After Cutting

After cutting, the ends of the light strip typically need to be connected to a power source or extension cord, or fitted with end caps.

Choose a connector that matches the light strip type. These typically use a snap-on design for quick and easy connection.

If light strip is temporarily unused or unconnected after being cut, be sure to seal it with dedicated insulating end caps or electrical tape to prevent short circuits.

Note on Cutting Light Strips

- Find the correct cutting point: This is most important step! Never cut at random. Carefully follow the strip and look for scissors symbol or vertical dashed line.

- Low-voltage light strips (12V or 24V DC): These are most common and suitable for DIY installations. They can be safely cut without disconnecting the power supply.

- High-voltage light strips (110V/220V AC): High-voltage light strips are often encased in silicone tubing and are extremely dangerous! Do not cut them yourself! Instead, have a professional electrician use a dedicated connector.

Cuttable LED Strip Light Types

Common cuttable types: monochrome light strip, RGB/RGBW light strip, addressable light strip, low-voltage COB/silicone light strip.

Most low-voltage light strips are cuttable, and it is safer to cut them yourself. Although high-voltage light strips can be cut, there is risk of electric leakage, so it is not recommended for non-professionals to operate.

| Voltage Type | Voltage | Cuttable | Reason |

|---|---|---|---|

| Low-voltage light strip | DC 12V/24V | Cuttable | Safe voltage. Designed with a cut point, suitable for DIY |

| High-voltage light strip | AC 110V/220V | Not cuttable | Cutting will expose high-voltage wires, posing a risk of electric shock! |

Cuttable light strips are designed with clearly marked cut points. Typically, there’s a cut point every three or six LEDs.

Strips without clear cut points should not be cut.

Cut To Size LED Lights

The size of light strip cut is also very important. The cut size varies for different scenes and light strip types.

- Random cutting can damage the circuit, leading to short circuits, burnout, or electrical leakage.

- Cutting at any point other than the shear point can sever internal wiring.

- Connectors/soldering require complete pads.

| Light Strip Type | Minimum Cut Length |

|---|---|

| Monochrome White Light Strip | 3 or 6 LEDs |

| RGB/RGBW Light Strip | 3 or 6 LEDs |

| Addressable Light Strip | 1 LED |

| COB Light Strip | 5-10 LEDs |

The length of the light strip directly affects the voltage stability. Too long will affect brightness of the light strip.

| Power Supply Voltage | Light Strip Type | Recommended Maximum Length |

|---|---|---|

| 12V DC | Standard SMD Light Strip | ≤ 5 meters |

| 24V DC | High-Density Light Strip | ≤ 10 meters |

| 5V DC | Addressable Light Strip | ≤ 2 meters |

Cutting Daybetter LED Lights Advice

The cutting point of the Daybetter light strip is usually marked with a yellow dotted line. The light strip must be cut at the cutting point. Finally, connect it with the connector that matches the light strip type.

Typical Difficulties When Cutting LED Strips

Cutting LED light strips may seem simple, but there are many technical difficulties that may be encountered in actual operation.

Preventing LED Pads Damage

The shearing point must be between the two sets of copper pads. When shearing, keep the force vertically downward to avoid shaking left and right. The copper LED pads should be cut carefully to prevent nicking or ripping, as this could make the strip useless.

Light strip connector compatibility

| Issue | Cause | Solution |

|---|---|---|

| LED strip does not light up after connection | Connector pins did not pierce insulation layer | Use a piercing connector and press firmly |

| Some LEDs flicker or dim | Poor contact increases resistance | Solder the wires or use high-resilience pin connectors |

| RGB strip shows incorrect colors | Pin order connected incorrectly | Reinsert according to the “+/R/G/B” labels on the strip |

Warning: A user cut an RGB light strip in the wrong place and then forced soldering, causing the controller to burn out. The correct approach is to stop cutting and replace the strip with a new one!

Dysfunction

The light strip does not light up at all after cutting.

The brightness of the end light strip decreases : The light strip is too long, resulting in insufficient voltage at the end.

Final Remark

Cutting LED strip lights is simple. Just remember:

- Confirm the cut point location.

- Ensure waterproof sealing after cutting.

- Ensure the circuit is intact at the cut point.

- Use genuine or compatible connectors or solder.

Follow the instructions in this chapter to ensure you don’t make mistakes when cutting LED tape.

People Also Ask

Can you cut LED light strips without damaging them?

As long as you cut along the designated LED strip lights cut line, you can cut LED light strips without damaging them.

For optimal effects, where should LED strips be cut?

For a working strip, always cut at the copper cut line.

If my LED strip stops working after cutting, what should I do?

The next step is to check the LED pads and reconnect using an appropriate LED light connector plug.

Can I DIY cut light strips?

Of course, but only low-voltage light strips can be DIY cut. High-voltage light strips have the risk of leakage and need to be cut by professionals.