Anti-Glare Solution for LED High Bay Light and How to Reduce It

Introduction to Glare in Industrial Lighting

Glare is a common issue in industrial lighting settings, where powerful LED high bay lights are used to illuminate large spaces like factories and warehouses. When workers look directly into these lights, they often experience glare, leading to discomfort and potential safety hazards. This article explores effective solutions to reduce glare in LED high bay lighting and answers common questions like "what is glare?" and "how to reduce glare from overhead lights."

Understanding Glare in LED Lighting

Glare occurs when there is excessive brightness or when light is unevenly distributed, causing visual discomfort. In LED lighting, glare is often a result of direct light exposure, where the light source is visible to the eye without any anti-glare measures. This issue is particularly pronounced in high bay lighting systems used in industrial environments.

Types of Glare

Glare can be classified into several types:

-

Direct Glare: Occurs when the light source is directly visible and too bright.

-

Reflective Glare: Happens when light reflects off surfaces like TV screens or machinery.

-

Discomfort Glare: Causes discomfort without necessarily reducing visibility.

-

Disability Glare: Reduces visibility and may cause temporary vision impairment.

Understanding these types is crucial when considering solutions to reduce glare in LED high bay lights.

Common Complaints: Glare in Industrial Settings

Many workers and operators in industrial settings often complain about glaring lights. They may describe ways by which glare affects their productivity and safety, asking questions like "how to reduce glare?" or "which of the following suggestions will help to avoid glare?" A frequent issue is the glare from lights reflecting off surfaces like TV screens, creating glare effects that hinder visibility and focus.

Solutions to Reduce Glare in LED High Bay Lights

LEDRHYTHM specializes in providing effective anti-glare solutions for LED high bay lights, particularly in industrial settings. Here are some of the best methods to reduce glare:

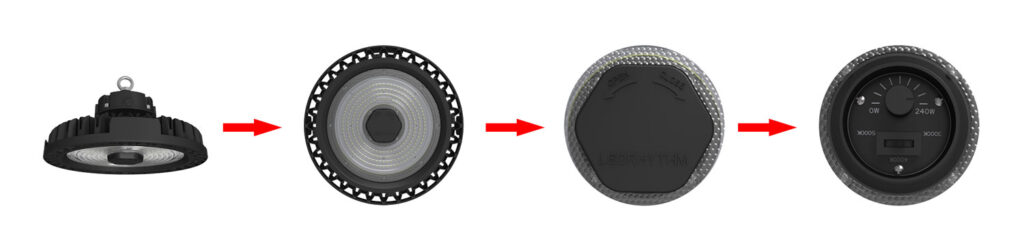

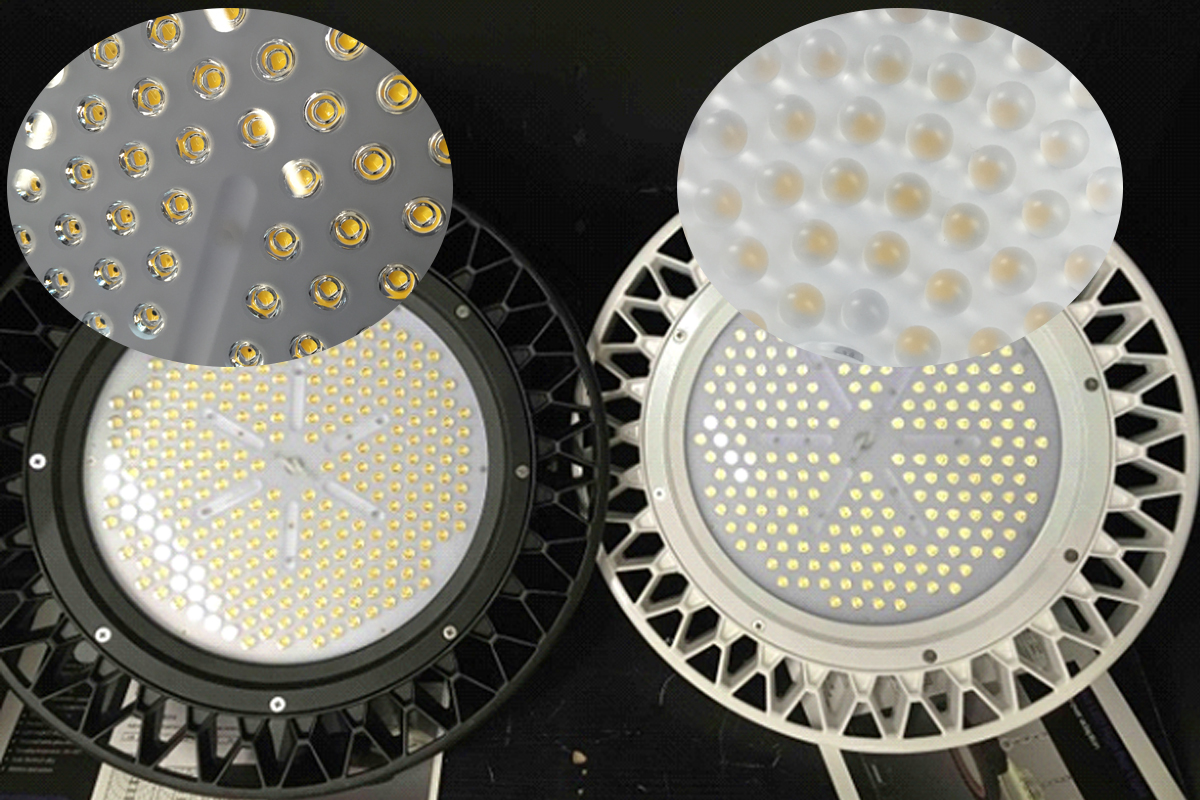

Solution 1: Optical Lens

An optical lens is one of the most effective solutions for reducing glare in LED high bay lights. By diffusing the light and improving its distribution, an optical lens minimizes direct exposure to the light source, significantly reducing light glare and creating a more comfortable environment for workers. This method is highly recommended for settings where lighting glare is a frequent issue.

Solution 2: Reflector

A reflector is another widely used option for reducing glare. Reflectors help redirect light in a way that minimizes direct exposure to the light source, thus reducing glare. Many customers in industrial environments opt for reflectors as they are effective in controlling glare and improving light distribution.

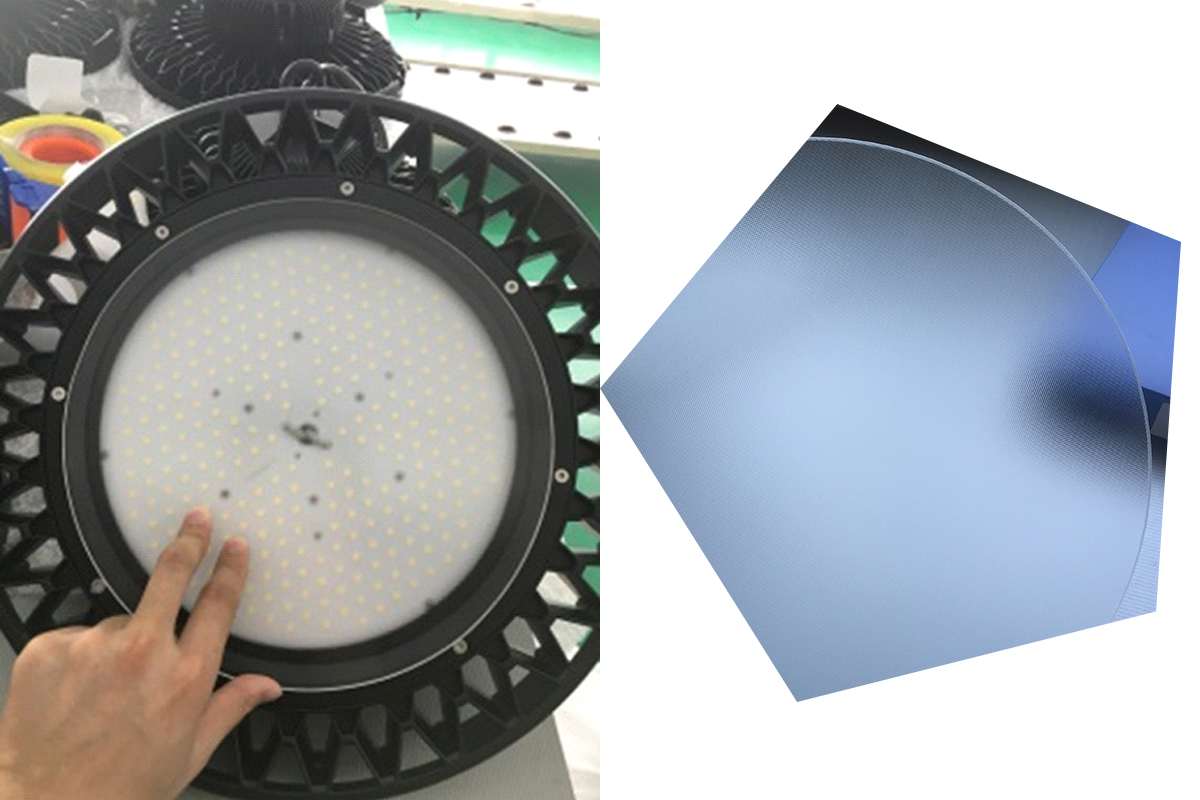

Solution 3: Milky Tempered Glass or Plastic Cover

Using a milky tempered glass or plastic cover over LED lights is another effective way to reduce glare. These covers diffuse the light, making it less intense and thus less likely to cause glare. This method is particularly useful in environments where low glare is essential, such as in factories where glare-free lighting is necessary for safety and productivity.

Combining Solutions for Maximum Effect

In many cases, combining two or more of the above solutions can provide even better results in reducing glare. For example:

-

Solution 1 & 2: Using an optical lens in conjunction with a reflector can greatly reduce light glare and improve overall lighting conditions.

-

Solution 2 & 3: Pairing a reflector with a milky tempered glass cover can further diffuse light, reducing the chance of glare and creating a more comfortable environment.

Special Considerations: Anti-Glare Light Bulbs

When selecting LED high bay lights, it's important to consider anti-glare light bulbs. These bulbs are designed to reduce glare by diffusing light more evenly. Some of the best options include no glare light bulbs, non glare light bulbs, and low glare light bulbs. These anti-glare light bulbs are especially useful in settings where glaring lights are a persistent problem.

Addressing Common Glare Issues in LED Lighting

Several common issues arise when dealing with glare in LED lighting:

-

Glare from lights: This is a widespread problem in factories and industrial environments. Solutions like optical lenses and reflectors can significantly reduce this issue.

-

Glare on TV screens: In some settings, glare from LED lights can cause reflections on TV screens or monitors. To reduce screen glare, consider using glare-free lighting or glare-reducing covers.

-

Glare when looking at lights: For workers who need to look up at lights frequently, anti-glare light covers can be installed to reduce glare.

DIY Solutions to Reduce Glare

For those looking to address glare issues on a budget, there are several DIY solutions available:

-

DIY flood light glare shield: Create a shield using materials like cardboard or metal to redirect light and reduce glare.

-

Light bulb glare shield: Install a shield over light bulbs to reduce glare in specific areas.

-

How to edit out light glare: For photographers or videographers, learning how to edit out light glare in post-production can be a valuable skill.

Glare-Free Lighting: The Future of Industrial Illumination

As technology advances, more solutions are becoming available to combat glare in industrial settings. Glare-free lighting is not just about comfort; it's also about safety and productivity. By choosing the right anti-glare solutions, factories and industrial facilities can create environments that are both efficient and comfortable for their workers.

Challenges with Energy-Saving LED Lights

While energy-saving LED lights are praised for their efficiency, they can sometimes create glaring problems. Common complaints include:

-

Are energy-saving LED lights also glaring? Yes, without proper anti-glare measures, these lights can cause significant glare.

-

Are energy-saving lights creating glaring problems? Some energy-saving options may contribute to glaring problems if not paired with glare-reducing technologies.

-

LED lights also creating glaring issues: This is particularly true in settings where high-intensity lighting is required.

Solutions to Address Glaring Problems in Energy-Saving LEDs

To address these issues, it's crucial to integrate anti-glare technologies into energy-saving LED systems. Using anti-glare light covers, optical lenses, or reflectors can mitigate the glare created by these lights.

Tables of Comparison: Anti-Glare Solutions

|

Solution |

Effectiveness |

Cost |

Best For |

|

Optical Lens |

High |

Moderate |

Industrial settings |

|

Reflector |

Medium-High |

Low |

Factories, Warehouses |

|

Milky Tempered Glass Cover |

Medium |

Low |

General anti-glare needs |

|

Anti-Glare Light Bulbs |

High |

Moderate |

Glare-free lighting |

|

DIY Glare Shield |

Medium |

Low |

Budget-conscious users |

Conclusion: Reducing Glare for Better Industrial Lighting

In conclusion, addressing glare in industrial settings is essential for creating a safe and productive environment. By understanding the causes of glare and implementing effective anti-glare solutions, factories and other industrial facilities can significantly improve their lighting conditions. Whether through the use of optical lenses, reflectors, or anti-glare light bulbs, there are numerous ways to reduce glare and enhance the overall lighting quality.

Below is a table comparing different anti-glare solutions for LED high bay lights:

By following the tips in this article, industrial operators can make sure their LED high bay lights shine brightly. This will help avoid discomfort and safety risks caused by glare.