Cómo elegir una luz de gran altura C¿almacenamiento antiguo? | LEDRHYTHM

Las cámaras frigoríficas son lugares donde se almacenan diversos productos, como alimentos, medicamentos, etc. En el entorno especial de las cámaras frigoríficas, la iluminación es muy importante. En el entorno especial de las cámaras frigoríficas, la iluminación es muy importante. Una buena iluminación no es sólo para que veamos el interior, también tiene un papel más importante. Así que tenemos que entender: ¿por qué el almacenamiento en frío debe elegir la iluminación profesional de almacenamiento en frío. y la iluminación de almacenamiento en frío no profesional puede traer esos problemas malos para el almacenamiento en frío.

Profesional iluminación de cámaras frigoríficas

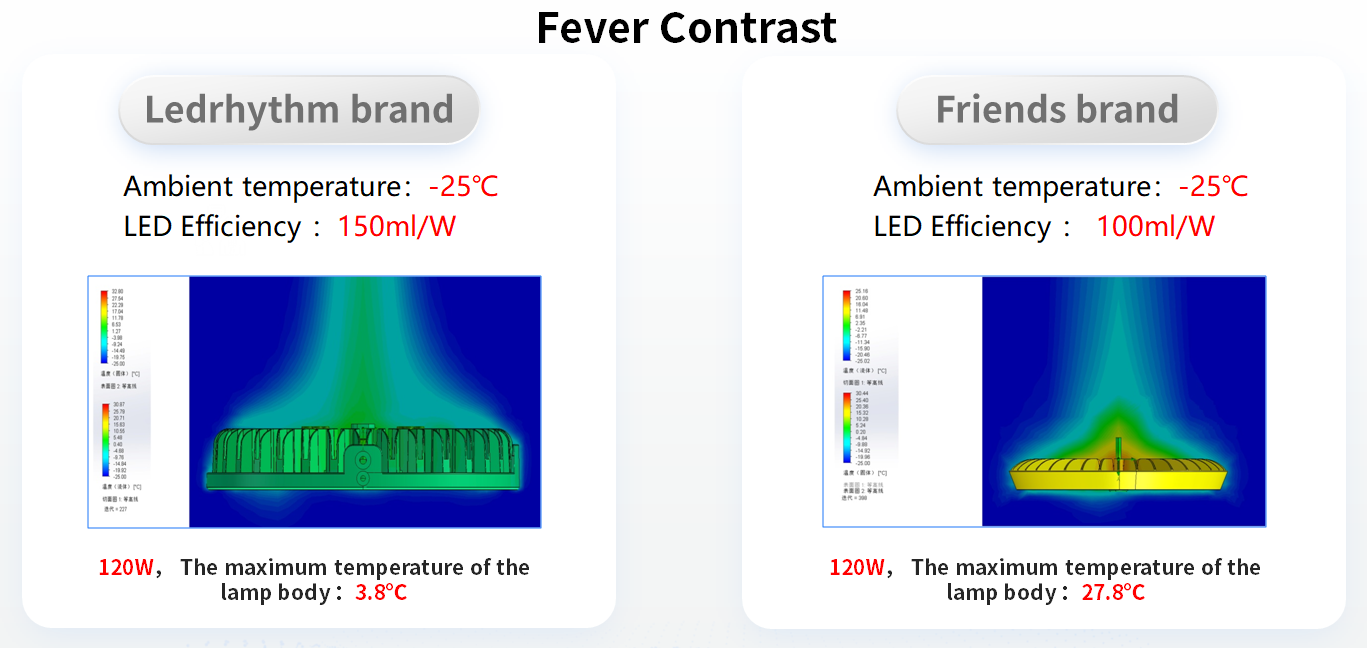

Resistencia al frío: Diseño profesional de iluminación para cámaras frigoríficas tiene en cuenta el entorno de bajas temperaturas, por lo que puede funcionar de forma estable en condiciones de frío extremo. La iluminación no profesional puede parpadear o incluso dañarse a bajas temperaturas.

Ahorro de energía: Los sistemas de iluminación profesionales suelen utilizar lámparas LED de bajo consumo. En comparación con la iluminación tradicional, los LED pueden reducir el consumo de energía en más de 50%. Esto reduce los costes de funcionamiento.

Larga vida útil: Las lámparas LED suelen tener una vida útil más larga, lo que reduce la frecuencia de mantenimiento y sustitución, así como los costes de mantenimiento.

Impermeable: La iluminación profesional para cámaras frigoríficas suele tener un mayor rendimiento a prueba de agua, adaptándose a entornos húmedos y reduciendo el riesgo de daños en las lámparas.

Personalización: El sistema de iluminación profesional puede personalizarse en función de las necesidades específicas de la cámara frigorífica para garantizar el mejor efecto de iluminación.

Poco profesional iluminación de cámaras frigoríficas:

Despilfarro de energía: La iluminación no profesional de las cámaras frigoríficas puede derrochar mucha energía y aumentar los costes de explotación.

Desnivel: Una iluminación desigual puede hacer que algunos lugares estén demasiado oscuros y otros demasiado iluminados, lo que afecta a la eficacia del trabajo.

Difícil mantenimiento: Las lámparas de baja calidad son propensas a fallar y requieren reparaciones y sustituciones frecuentes, lo que aumenta los costes de mantenimiento.

Riesgo para la seguridad: Una iluminación insuficiente puede hacer que los trabajadores tropiecen o se golpeen con las mercancías almacenadas en frío, lo que aumenta los riesgos para la seguridad.

Ventajas de las soluciones profesionales de iluminación para cámaras frigoríficas LEDRHYTHM

LEDRHYTHM cuenta con un experimento profesional de simulación de almacenamiento en frío. Cada lámpara profesional de almacenamiento en frío se ha sometido a rigurosos experimentos y se ha utilizado en muchos proyectos de almacenamiento en frío, recibiendo evaluaciones de alta calidad de los clientes. Con ingenieros ópticos profesionales de simulación de almacenamiento en frío, podemos simular soluciones profesionales de iluminación de almacenamiento en frío de acuerdo con el sitio real.