目录

切换导言

LED 照明技术已成为现代照明解决方案的革命性力量。与传统照明方法相比,LED(发光二极管)灯具有明显的节能效果、卓越的亮度和更长的使用寿命,在家庭、工业和户外环境中得到了广泛的普及。但是,LED 灯是如何制造的,生产过程中涉及哪些材料?

LED 灯由什么制成?

LED 材料包括 LED 芯片、荧光粉、基板、散热器、电路板、电子元件、外壳、反射器、透镜。

光源

LED 的光源是负责发光的 LED 芯片。芯片被放置在基板上,并封装有荧光粉涂层(对于白光 LED),以改变光的亮度。 发射光的颜色。

驱动和控制

LED 驱动器是调节电流并确保向 LED 芯片输送正确功率的重要组件。它将电源中的交流电(AC)转换为 LED 工作所需的直流电(DC)。

散热

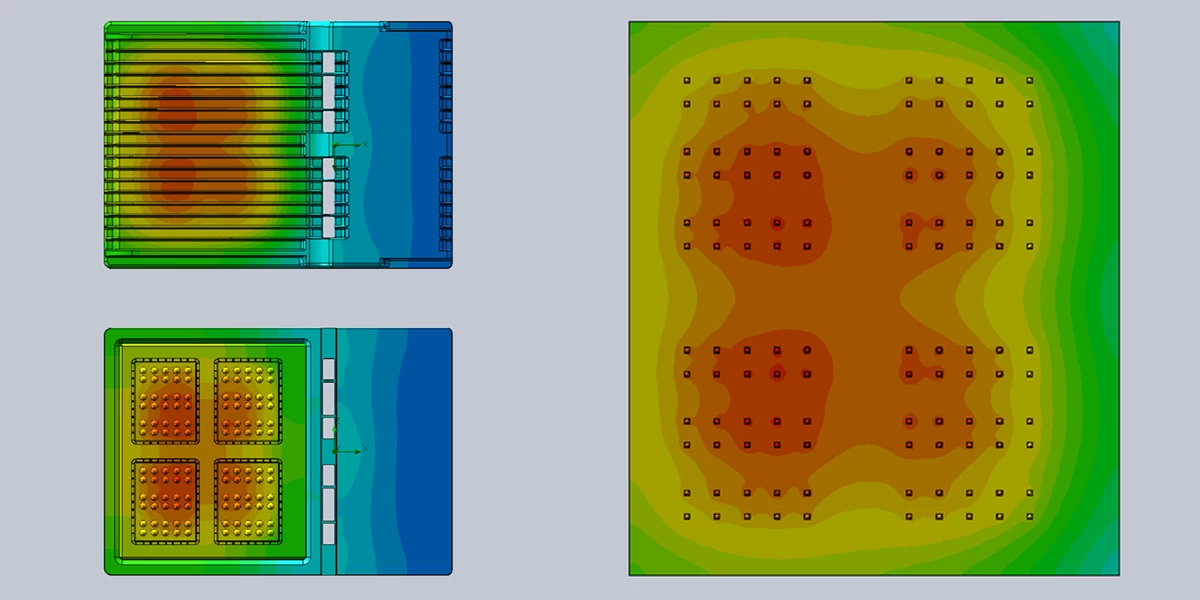

过多的热量会降低 LED 芯片的性能,缩短其使用寿命。LED 灯中使用的散热器通常由铝制成,用于将热量从 LED 芯片中吸走并安全散出。此外,芯片和散热器之间还使用导热脂来填充缝隙,以提高热传导效率。

结构和光学

透镜/反射器通常用于 LED 灯中,以控制光的分布,根据应用进行聚焦或漫射。透镜通常由玻璃或塑料等耐用材料制成,其设计目的是通过将光线引导到需要的地方来提高 LED 的性能和效率。

LED 灯外壳由压铸铝或塑料制成,集成了所有组件并保护灯具。

LED 灯材料完整的桌子:

| 组件 | 功能 | 常用材料/说明 |

|---|---|---|

| LED 芯片(发射器) | 将电能转化为光能 | 氮化镓/氮化铟/砷化镓半导体材料 |

| 荧光粉 | 将蓝光/紫外线 LED 灯转换为白光或其他色温的光 | YAG:Ce 硅酸盐荧光粉;作为涂层使用 |

| 基板/印刷电路板 | 为芯片提供机械支持和热路径 | 铝基板、铜基板、陶瓷基板 |

| 散热器/热管理 | 散热以保持性能和使用寿命 | 铝挤压/压铸件、铜、热界面材料 |

| 驱动器/电源 | 将电源转换为 LED 的恒定电流/电压 | 集成电路、电容器、电感器;封装在塑料或金属外壳中 |

| 镜头/光学器件 | 控制光线分布和光束角度 | PMMA(丙烯酸)、PC(聚碳酸酯)、玻璃 |

| 反射器/二次光学器件 | 改善光的均匀性并引导流明输出 | 铝涂层塑料、阳极氧化铝 |

| 外壳 | 保护内部零件并提供安装 | 铝、钢、PC/ABS 塑料;粉末涂层或阳极氧化处理 |

| 密封件和垫圈 | 提供入口保护和抗震性 | 硅树脂、三元乙丙橡胶、聚氨酯浇注 |

| 连接器和接线 | 驱动器、LED 和电源之间的电气连接 | 铜线、接线端子、焊点、线束 |

LED 是如何制造的?

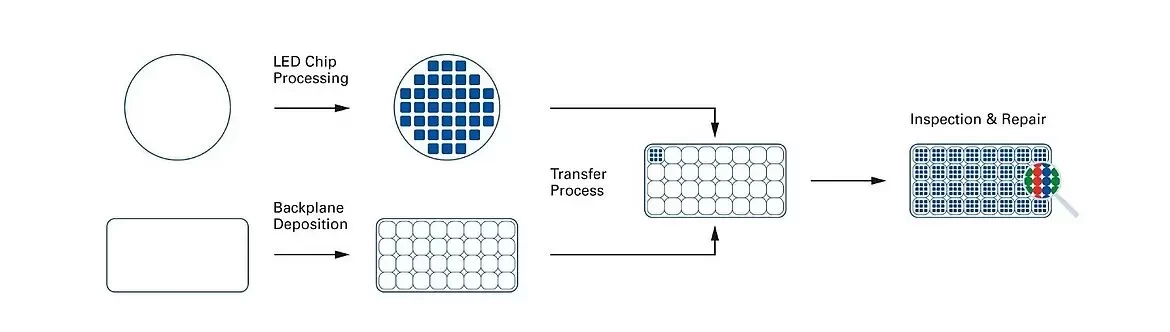

从半导体晶片的制备到照明产品的最终组装,LED 的制造过程涉及多个步骤。下面概述了 LED 灯的制造过程。

- 半导体材料制备

LED 制造的第一步是制备半导体材料,通常是氮化镓(GaN)或砷化镓(GaAs)。这些材料用于制造半导体晶片,然后将晶片切成薄层。 - LED 芯片制造

然后对半导体晶片进行加工,制成 LED 芯片。加工过程包括

掺杂:在半导体材料中引入杂质,形成对二极管功能至关重要的 p 型和 n 型区域。

蚀刻:制作 LED 芯片的发光表面。 - 磷涂层

就白光 LED 而言,在 LED 芯片上会涂上一层荧光粉。荧光粉能将 LED 芯片发出的蓝光或紫外光转换成宽光谱的可见光,通常是白光。 - 组件组装

LED 芯片安装在基板上,并与驱动器、散热器和其他重要组件相连。然后再加上透镜,以控制发射光的分布。 - 测试和质量控制

组装完成后,每个 LED 都要经过性能测试,包括亮度、色彩准确度和能效。严格的质量控制措施确保最终产品符合必要的标准。

LED 生产设施的工艺流程是什么?

研发与设计

这一过程始于研发(R&D),由工程师设计新的 LED 产品并优化现有设计以提高性能。创新可能包括半导体材料、LED 芯片设计和散热技术方面的进步。

实验室研究

在实验室中,科学家们对 LED 芯片进行材料分析和性能测试,以优化发光效率,确保最高质量的光输出。目的是提高半导体晶片的可靠性和最终 LED 产品的使用寿命。

工具和机械制造

在这一阶段,开发用于 LED 生产工艺的工具机械。专门设计的机器用于制造组装 LED 所需的半导体晶片和其他组件。

聚酯成型机和发泡设备

聚酯模塑机用于将 LED 芯片封装在保护材料中,使其防潮并免受环境因素的影响。这一步骤对于确保最终产品的耐用性和可靠性至关重要。

部件组装

LED 芯片与散热器、驱动器和透镜等其他组件经过精心组装。这一过程可确保 LED 灯正常工作,并可在各种应用中使用。

测试和质量控制

组装完成后,每个 LED 灯都要经过严格的测试,以确保其符合性能和安全标准。测试包括

- 发光效率

- 电气性能

- 散热

- 防水和耐环境性

摘要

LED 照明技术代表着节能照明解决方案的重大飞跃。通过了解 LED 照明是由什么构成的以及 LED 生产的工艺流程,我们可以清楚地看到,LED 灯的生产涉及尖端技术、精密工程和半导体等先进材料。

Ledrhythm 拥有完整的 LED 照明制造系统。查看我们的 质量控制 和 公司信息.请随时 联系我们 定制您的 LED 照明解决方案。

人们还会问

发光二极管如何发光?

LED 的发光原理是,当电流通过半导体材料制成的 PN 结时,电子和空穴会在结区重新结合并释放能量。这些能量以光子的形式发射出来,从而产生可见光或其他波段的光。

- 半导体 PN:发光的基本结构。

- 电子-空穴重组:发光的物理过程。

- 以光子形式释放的能量:在重组过程中转化为光的能量。

- 电致发光:电致发光:电能直接转化为光。

用于制造灯具的 LED 材料有哪些?

LED 灯主要由 LED 芯片、包装材料、驱动电路、散热器、透镜和外壳组成。

LED 制造工艺复杂吗?

是的,LED 制造过程确实复杂,技术难度大,涉及各种精密工艺,如半导体物理、材料科学、热力学和光学工程。