Table des matières

ToggleIntroduction

L'éclairage LED intégré est devenu une solution révolutionnaire dans les applications industrielles, commerciales et d'éclairage extérieur telles que les usines, les ports et les stades. L'éclairage LED intégré se réfère à l'éclairage où le module LED est intégré dans le luminaire lui-même, plutôt que de dépendre d'une ampoule séparée et remplaçable.

Cette conception présente plusieurs avantages, tels qu'une meilleure efficacité énergétique, une durée de vie plus longue et une meilleure gestion de la chaleur. Toutefois, elle soulève également des questions, telles que la durée de vie des lampes à LED intégrées et la possibilité de les remplacer en cas de défaillance.

Qu'est-ce qu'une lampe à LED intégrée ?

Les systèmes d'éclairage LED intégrés incorporent les puces LED directement dans le luminaire, faisant de la puce LED et du luminaire un tout, plutôt que de dépendre d'une ampoule LED séparée. Le luminaire est conçu pour durer toute la durée de vie de la LED elle-même, généralement plus de 50 000 heures. Ces systèmes sont populaires dans les environnements industriels en raison de leur durabilité et du peu d'entretien qu'ils nécessitent.

Caractéristiques principales des lampes LED intégrées :

- Source lumineuse non remplaçable : La puce LED est directement soudée ou fixée au circuit imprimé, ce qui rend impossible de la détacher comme on le ferait en dévissant une ampoule LED.

- Conception intégrée : L'extérieur de la lampe, la conception optique, la structure de dissipation de la chaleur (plaque de base en aluminium, ailettes de dissipation de la chaleur) et le circuit d'attaque sont tous conçus sur mesure pour obtenir des performances d'éclairage optimales.

- Longue durée de vie : Grâce à l'utilisation de puces LED de haute qualité, d'un pilote compatible et d'une excellente dissipation de la chaleur, la durée de vie théorique est très longue, atteignant généralement 50 000 heures ou plus.

Composants de l'éclairage LED intégré :

L'éclairage LED se compose de plusieurs éléments qui fonctionnent ensemble pour produire une lumière brillante et efficace :

- Perles LED : Composées de supports, de colle argentée, de puces, de fils d'or et de résine époxy.

- Cartes de circuits imprimés : Fournissent la structure et la conductivité pour les perles LED.

- Boîtier et lentilles : Protègent la LED et aident à répartir la lumière de manière homogène.

- Pilotes de LED : convertissent le courant alternatif en courant continu requis par la LED, garantissant ainsi une utilisation efficace de l'énergie.

La conception de l'éclairage LED intégré intègre ces composants en une seule unité cohésive. Il en résulte une conception rationalisée, compacte et optimisée en termes de performances. Mais la comparaison entre les LED intégrées et non intégrées ne s'arrête pas à la structure ; elle s'étend également aux performances et à la flexibilité.

Éclairage LED intégré ou divisé

La source lumineuse, l'alimentation électrique et le dissipateur thermique de l'éclairage LED intégré forment un tout ; la source lumineuse, l'alimentation électrique et le dissipateur thermique de l'éclairage LED divisé sont séparés et peuvent être remplacés individuellement.

| Fonctionnalité | LED intégrée | LED traditionnelles (ampoules/tubes) |

|---|---|---|

| Source lumineuse | Intégré, non remplaçable | Ampoules facilement remplaçables (par exemple, E27) |

| Conception | Aspect moderne, mince et sans couture | Limité par le type de prise, conception simple |

| Performance | Optique optimisée, meilleure dissipation de la chaleur | Dépend de la compatibilité entre l'ampoule et le luminaire |

| Coût de la maintenance | Élevé - remplacement complet de l'appareil | Faible - remplacer l'ampoule ou le conducteur uniquement |

| Coût initial | Coût initial plus élevé | Investissement initial moins élevé |

| Évolutivité | Pas de mise à niveau possible, remplacement de l'ensemble de l'unité | Mise à niveau facile avec des ampoules plus récentes |

| Durabilité | Durée de vie généralement plus longue, moins de pièces détachées | Peut se dégrader plus rapidement, en fonction de la qualité de l'ampoule |

| Scintillement | Sortie stable, scintillement minimal | Plus de risque de scintillement avec des conducteurs bon marché |

Avantages et inconvénients de l'éclairage LED intégré

Avantages

- Esthétiquement agréable : Le design minimaliste et ultra-mince offre un effet visuel étonnant, se fondant parfaitement dans un décor moderne.

- Performance optique : Les fabricants peuvent personnaliser la lentille pour l'adapter à la forme de l'appareil, afin d'obtenir une distribution optimale de la lumière.

- Dissipation de la chaleur : La conception intégrée de la dissipation de la chaleur permet de dissiper efficacement la chaleur de la puce, ce qui prolonge la durée de vie de la LED.

- Longue durée de vie : Grâce à une excellente dissipation de la chaleur et à un pilote de haute qualité, la durée de vie dépasse de loin celle des ampoules LED remplaçables.

- Peu d'entretien : Aucun remplacement régulier des ampoules n'est nécessaire, ce qui en fait une solution d'éclairage idéale pour les espaces à hauts plafonds, les entrepôts et les grandes installations.

Inconvénients

- Réparation peu pratique : C'est le principal inconvénient. Que la puce, l'alimentation ou le câblage soient endommagés, l'ensemble du luminaire doit être remplacé, ce qui est beaucoup plus coûteux que le remplacement d'une seule ampoule.

- Des progrès technologiques rapides : Une lampe achetée aujourd'hui sera peut-être plus économe en énergie et offrira une meilleure qualité de lumière dans quelques années. Cependant, la source lumineuse elle-même ne peut pas être mise à niveau.

- Attention à l'achat : Ces lampes ne pouvant être remplacées, des normes plus strictes doivent être respectées en ce qui concerne la luminosité, la température de couleur, l'indice de rendu des couleurs, la qualité et le service après-vente.

Remplacement des LED intégré

Le remplacement d'un éclairage LED intégré est plus compliqué que celui d'une ampoule traditionnelle, mais il est tout à fait possible de le faire soi-même. Comme indiqué précédemment, le "remplacement" d'un éclairage LED intégré ne signifie pas le remplacement de la puce LED, mais le remplacement de l'ensemble de l'éclairage.

Pour les professionnels de la maintenance, quelques composants des lampes LED intégrées peuvent également être remplacés, mais ils doivent s'adresser au fabricant pour obtenir des composants identiques. Pour les utilisateurs ordinaires : Le remplacement de l'ensemble des lampes permet de gagner du temps et les réparations ne sont pas rentables.

- Le conducteur et la lentille peuvent parfois être remplacés séparément ;

- Le module de la source lumineuse est essentiellement irremplaçable.

- Dans la plupart des cas, si une LED intégrée tombe en panne, il est préférable de remplacer l'ensemble de la lampe.

| Option | Avantages | Inconvénients |

|---|---|---|

| Réparation (remplacement du conducteur / de la lentille) | Coût réduit à court terme Respect de l'environnement Possible pour des défauts mineurs | Nécessite des compétences techniques La disponibilité des pièces n'est pas garantie Risque d'inadéquation des couleurs et de la luminosité |

| Remplacer l'ensemble du luminaire | Rapide et facile Garantit des performances constantes Garantie généralement couverte | Coût initial plus élevé Déchets de matériaux Moins durable à long terme |

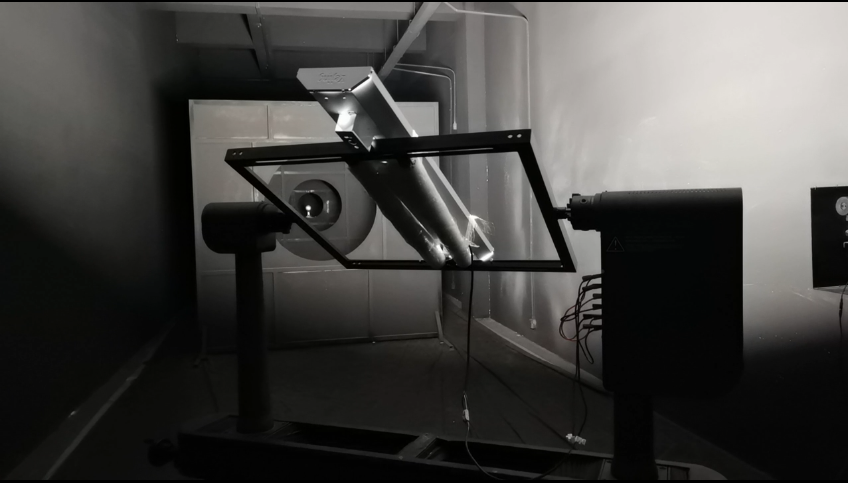

Type de lumière LED intégrée

Les lampes LED intégrées sont une tendance dominante dans la conception moderne de l'éclairage et sont maintenant utilisées dans la plupart des scénarios. Bien qu'une défaillance puisse nécessiter le remplacement complet de l'appareil, dans des circonstances normales, les défaillances sont rares. Les exemples incluent les panneaux lumineux à LED, les lumières linéaires, les lumières en hauteur et les projecteurs.

Nous sommes un fabricant professionnel d'éclairage LED, fournissant une variété d'éclairage LED intégré pour l'industrie, le commerce, le sport, la route et d'autres domaines. Vous pouvez voir tous nos produits ou nous contacter pour une solution d'éclairage personnalisée.

| Catégorie | Type d'appareil | Caractéristiques | Applications typiques |

|---|---|---|---|

| Home / Commercial | Panneau lumineux | Module de commande et de LED mince et intégré | Bureaux, habitations, magasins de détail |

| Downlight | Design compact et encastré, LED intégrée | Salons, couloirs, hôtels | |

| Track Light | Module LED intégré avec tête réglable | Boutiques, galeries, salles d'exposition | |

| Plafonnier | Montage en surface, pilote + LED intégrés | Chambres, cuisines, espaces publics | |

| Industriel / Extérieur | Lumière en saillie | Design UFO, pilote intégré, refroidissement puissant | Entrepôts, usines, gymnases |

| Feu de croisement | Boîtier compact, LED + optique intégrées | Façades de bâtiments, panneaux d'affichage, cours | |

| Eclairage public | Module intégré ou conception monobloc | Routes, autoroutes, parkings | |

| Lumière Tri-proof | Corps scellé, étanche à l'eau, à la poussière et à la corrosion | Usines, tunnels, environnements humides |

Conclusion

L'avenir de l'éclairage s'oriente indubitablement vers l'éclairage LED intégré. Bien qu'il y ait quelques inconvénients, comme la difficulté de remplacer les LED défectueuses, les avantages l'emportent largement sur ces préoccupations, en particulier dans les applications industrielles telles que les usines, les ports et les stades. Les avantages et les inconvénients des éclairages à LED intégrés démontrent que pour la plupart des environnements industriels, les LED intégrées offrent une durabilité et une fiabilité à long terme inégalées.

Les gens demandent aussi

Les lampes LED intégrées sont-elles courantes dans l'éclairage extérieur ?

En effet, de nombreux luminaires extérieurs sont intégrés. Les principales raisons sont les suivantes :

- Niveau de protection plus élevé : Les conceptions de LED intégrées sont plus susceptibles d'atteindre les niveaux IP65-IP67 (scellées, étanches et résistantes à la poussière).

- Installation facile : Pour les projets nécessitant une installation rapide, les luminaires LED intégrés sont prêts à l'emploi et ne nécessitent qu'une alimentation électrique.

- Considérations de coût : Les appareils intégrés se caractérisent par une production standardisée, une taille compacte et des coûts de transport et d'installation réduits.

Quelle est la durée de vie des lampes à DEL intégrées ?

La durée de vie théorique des lampes LED intégrées peut atteindre 30 000 à 100 000 heures, mais la durée de vie réelle dépend de l'alimentation du pilote, de la dissipation thermique et de l'environnement de fonctionnement.

Les produits de qualité industrielle ont généralement une durée de vie plus longue, de l'ordre de 50 000 à 100 000 heures. Les produits de qualité domestique ont tendance à avoir une durée de vie plus courte.

Qu'est-ce qu'une ampoule LED intégrée? ?

Une ampoule LED intégrée signifie que la puce LED, l'alimentation du pilote et les composants de dissipation thermique sont tous encapsulés à l'intérieur de l'ampoule, formant ainsi un ensemble indémontable.