LEDランプビード配置機のランプビード配置工程|LEDRHYTHM

LEDランプを製造している当社の生産工場へようこそ。当社の生産ラインには、非常に重要な設備があることにお気づきでしょうか。

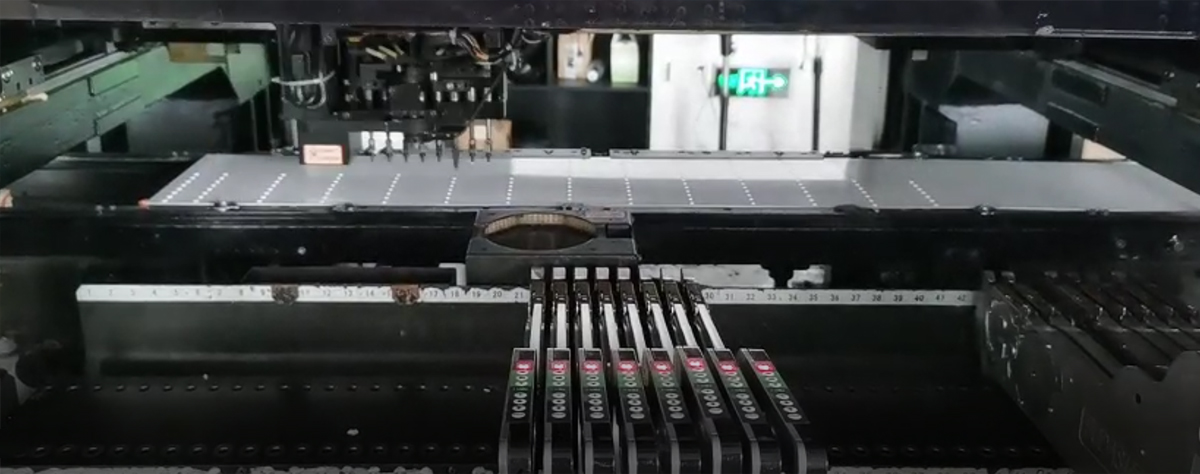

この機械は、LEDランプビーズを素早く正確にランプに取り付けることができるため、非常に重要です。その動作原理は、精密なメカニカルアームとセンサーによって、LEDランプビーズを所定の位置に正確に配置できるというものです。この工程は自動化されており、LED照明器具をより高い効率と品質で生産することができます。

LEDランプビーズ配置機は単なる機械ではなく、生産ラインにおける「スマートワーカー」でもあります。製造指示を読んで理解し、複雑なアルゴリズムによって最適な配置経路を決定し、作業中の異常状態を検知してフィードバックすることもできます。その助けによって、私たちは生産工程をよりよく管理し、製品の品質と一貫性を向上させることができるのです。

また、弊社のLEDランプが非常に高品質で、優れた性能を持っていることにお気づきかもしれません。これは、高品質のLEDランプビーズを使用しているからだけではなく、この先進的なLEDランプビーズ配置機の助けを借りて、各ランプビーズが正しい位置と角度に配置できるようにしているからです。配置

LEDランプビーズ配置機は、弊社が高品質のLEDランプを生産するための重要なツールです。自動化と知能化により、生産効率と品質を向上させ、お客様により良い製品とサービスを提供することができます。