目次

トグル1.はじめに

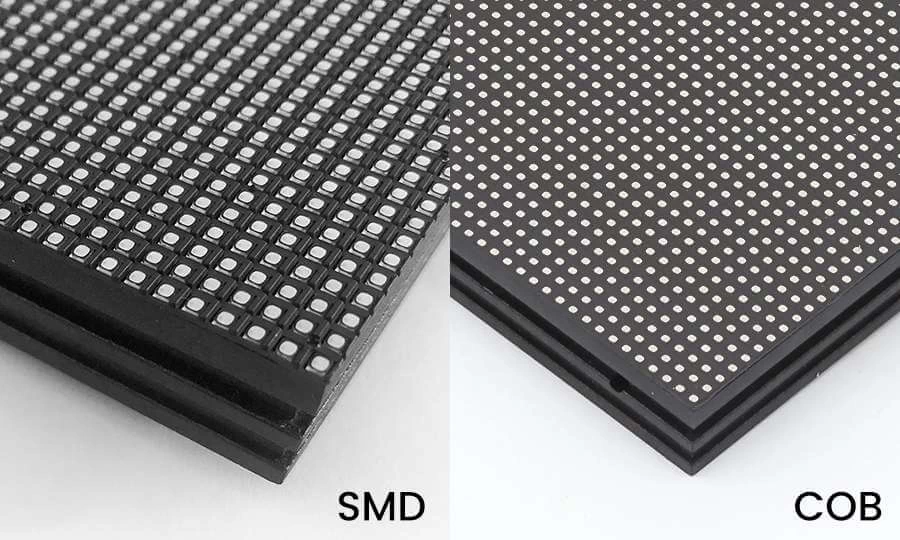

LEDのパッケージ方式には、SMD、COB、MCOB、CSP、DOB、EMC、FC、AC LEDなどがある。SMDとCOBはいずれもLEDの実装方法(発光チップの取り付け方、配線方法、熱伝導方法)であり、ランプの発光角度、明るさ、放熱能力、寿命などに影響を与える。この章では、SMDとCOBについて説明する。

2.SMDとは

SMDはSurface-Mounted Deviceの略で、最も広く使用されている成熟したLEDパッケージング技術である。単一のLEDチップは、金属ピン(パッド)を備えたプラスチックまたはセラミックのシェルにパッケージされている。このパッケージ化された独立デバイスは、表面実装技術によってプリント基板に直接はんだ付けすることができる。

特徴

- ディスクリートデバイス:各SMDパッケージには通常1個(場合によっては2~4個)のLEDチップが入っている。

- 標準化:様々な標準サイズ(3528、2835、5050、3030、5630など)があり、生産と設計の自動化が容易である。

- 点光源の特性:単一のSMDは小さな点光源である。複数のSMDを組み合わせて使用する。

- 柔軟性:PCB上にフレキシブルに配置でき、さまざまな形状(ライトストリップ、モジュール、電球のライトボードなど)に設計できる。

- 光学設計:各SMDは通常、二次光学設計のために独立したレンズまたは反射鏡カップに合わせる必要がある。

3.COBとは

COBの略(Chip-on-Board)は、より統合されたパッケージング技術である。複数の(通常は数十から数百の)カプセル化されていない裸のLEDチップが、同じ基板(通常は金属カストディまたはセラミック基板)上に直接固化され、はんだ付けされ、電気的に相互接続され、次に全体的に共通の蛍光体層で覆われ(大面積の発光面を形成する)、最後に保護レンズ層で覆われることがある。

特徴

- 集積光源:COBモジュールは、複数のチップを含む集積光源である。

- 面光源特性:比較的均一で連続的な発光面を持ち、スポットがソフトでフレアが少ない。

- 高密度:高電力密度を達成するために、チップは非常に小さな領域に密に配置されている。

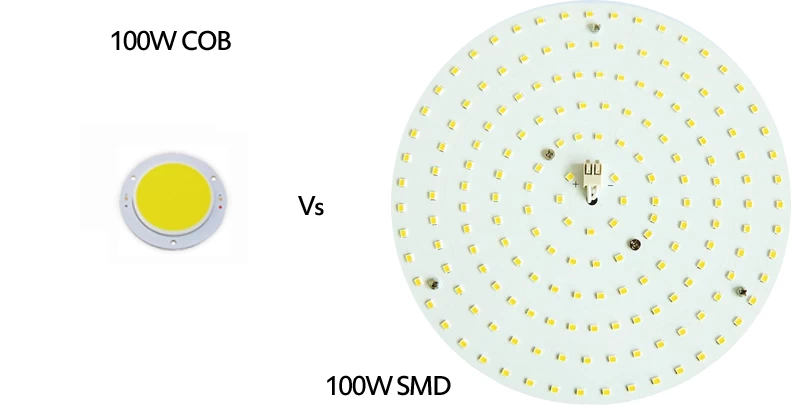

- 組み立ての簡素化:何十個ものSMDデバイスの代わりに、照明器具の製造ではCOB光源モジュールを1つだけ扱えばよい。

- 簡素化された光学系:通常、COB発光面全体をカバーするレンズやリフレクターは1枚で済む。

4.SMD LEDとCOB LEDの違い

- 基本構造:SMDは、単一または少数のチップをピンで独立してパッケージ化し、PCBに実装したものである。COBは、複数のベアチップを基板上に直接集積し、共通の蛍光体層で覆ったもの。

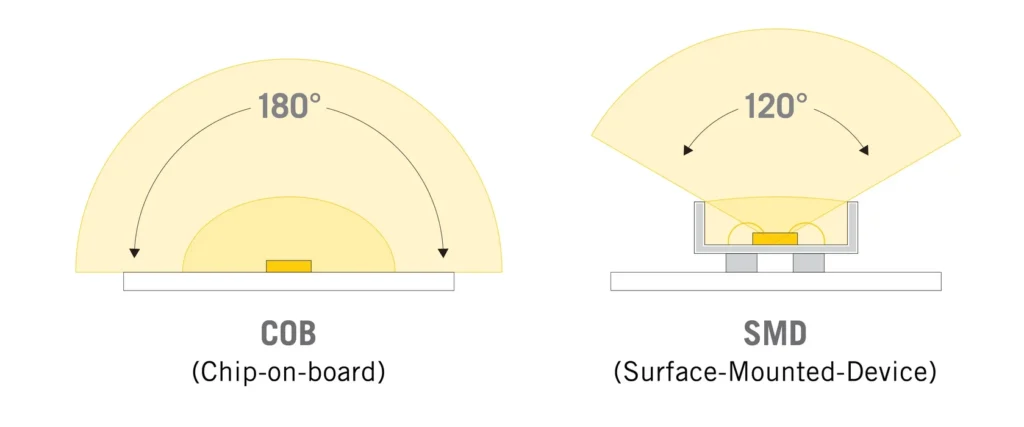

- 光源特性:SMDは点光源(複数の点の組み合わせ)。COBは面光源(単一の均一な発光面)。

- 発光効率:SMD、高い(特に低中出力域で)。実験データでは最大220 lm/W+、商用主流は120-180 lm/W。COB:理論的可能性は高いが、高密度に配置された熱管理上の課題により、同じ電力ではトップSMDより若干低い(その差は縮まっている)。商業的主流は100-160 lm/W。

- パワー密度:SMD、中程度。単一デバイスの出力には限界があり(通常1W未満)、高出力を実現するには複数の組み合わせが必要。COB:高。非常に小さな面積に複数のチップが集積されているため、1つのモジュールで高出力を実現しやすい(10W、20W、50W、100W以上)。

- 設計柔軟性:SMD、非常に高い。様々な形状、サイズ、出力、配光要件(直線、円形、特殊形状など)に合わせて自由に配置できる。COB:比較的低い。発光面の形状が固定されており(主に円形、正方形、長方形)、出力と配光は主にモジュールモデルによって決定される。

- 核心用途:SMDは、柔軟性、標準化、コスト効率の高いLED光源ソリューションを提供し、多様化、中小電力シナリオに適している。COBは、高出力密度、高光束、均一でソフトな光、優れた熱管理機能を持つ統合型光源を提供し、高輝度・高品質照明のニーズを満たし、ランプの製造を簡素化することができる。

5.SMD LEDとCOB LEDの長所と短所

5.1 光の質

SMD:メリットは、幅広い演色性と正確な色温度制御。デメリットは、複数の点光源を組み合わせるため、多重影、粒状性、グレアになりやすいこと(優れた光学設計が必要)。

COB:長所は、均一でソフトな光、自然なスポット光移行、良好なグレアコントロール、高い視覚的快適性。デメリットは、演色性がトップSMDより若干劣ること(改善中)、色温度の均一性のコントロールが若干難しいこと(精密な蛍光体コーティングが必要)。

5.2 熱管理

SMD:メリットは、1つのチップから発生する熱が分散され、熱経路が比較的短いこと(チップ→パッケージ→PCB→ヒートシンク)。デメリットは、複数のデバイスを組み合わせる場合、PCBの熱設計が複雑になり、優れた熱伝導材料とヒートシンクが必要になることです。

COB:利点は、チップが熱伝導性の高い基板(多くの場合セラミックや金属)に直接結合していることで、熱抵抗が低く、熱源から熱が排出されやすい。欠点は、熱が非常に集中するため、より強力な冷却ソリューション(大型ヒートシンク/アクティブ冷却)が必要になることである。

5.3 信頼性

SMD:利点は、技術が成熟しており、1つのデバイスの故障がローカル・エリアに影響することである。欠点は、はんだ接合部(デバイス・ピン→PCB)が多く、潜在的な故障箇所が多いこと。熱サイクル・ストレスがはんだ接合部の寿命に影響する可能性がある。

COB:利点は、はんだ接合部が少なく(チップが基板に直接はんだ付けされる)、構造がより強固で、機械的振動に対する耐性が高い。欠点は、1つのチップの故障がモジュール全体の故障や光色の異常を引き起こす可能性があること、蛍光体層が大きく、局所的な損傷が全体に影響すること。

5.4 コスト

SMD:長所は、標準化された部品、成熟した自動生産、低い初期部品コスト。デメリットは、組み立て工程(チップ実装、リフローはんだ付け)が多く、PCB設計が複雑なこと。

COB:メリットは、ランプの組み立て工程が簡略化され(光源モジュールの加工が1つで済む)、人件費と製造コストを削減できること。デメリットは、COBモジュール自体の製造コストが高いこと(基板、固体結晶、蛍光体コーティング工程)、メンテナンスコストが高いこと(通常はモジュール全体を交換)。

6.SMD 対 COB アプリケーション

- SMD:比較的均一な放熱と配光を実現し、照射角が広い。例えば、パネルライト、デスクランプ、投光器など。

- COB:集中光源とスポットライトを提供し、高輝度を実現する。フラッシュライト、スポットライト、ステージライトなど。

| 器具タイプ | 代表的なLEDパッケージ | 備考 / 好ましい場合 |

|---|---|---|

| パネル/トロファー | SMD | 大きく均一な発光面。高い効率と均一な拡散を実現しやすい。 |

| リニア/バテン/トランク | SMD | 連続運転と幅広ビーム、柔軟なレイアウト、倉庫や小売店で一般的。 |

| トライプルーフ(IP65/66) | SMD | 細長く均一な出力、良好な熱分布と過酷な現場での信頼性。 |

| 街路灯/エリアライト | SMD(主流) / COB(一部レガシー/スペシャル) | SMDアレイ+レンズで正確な路面分布を実現、COBはタイトなビームやレトロフィットが必要な場合に使用。 |

| フラッドライト(広域) | SMDまたはCOB | SMDは広く均一なウォッシュ用、COBは狭い光学系やロングスロー狙いのハイパンチ用。 |

| ハイベイ(UFO/リニア) | SMDまたはCOB | SMDは広く均一な通路をカバーし、COBはコンパクトな高ルーメンパッケージとタイトなビームを実現。 |

| ダウンライト(業務用) | COB(メインストリーム)/ SMD(ワイドビーム) | COBは、クリーンなセンタービームと高いCBCPを実現し、SMDバージョンは、よりワイドでソフトなビームを好む。 |

| スポット / トラック / アクセント | COB | 高いセンタービーム強度、引き締まった光学系、鮮明なシャドー、商品やギャラリーに最適。 |

| ステージ/スタジオ/フォロースポット | COB | コントロール可能なビームによる高いルーメン密度、アクセサリーとの良好なカラーミキシング。 |

| キャノピー/ウォールパック | SMD (共通)/COB(小型高出力) | SMDはエントランス周辺を広くカバー、COBは小型で高パンチを実現。 |

| 建築ウォッシュ/グレージング | SMD | リニアSMDアレイは、ファインピクセルピッチでスムーズなウォールウォッシュとグレージングを可能にする。 |

| ポータブル/懐中電灯/ヘッドランプ | COB (コンパクトモジュール) / SMD (パネルスタイル) | COBは集光ビーム用、SMDは作業灯の幅広いタスクライト用。 |

7.まとめとSMD、COB選択の提案

より高い発光効率と小型化を追求するSMD(例:Micro LED)と、発光効率、演色性、信頼性、コスト削減を向上させ続けるCOB、どちらも進化している。現在、SMDとCOBは、それぞれの得意分野で重要な役割を果たしながら、市場で補完的に共存している。

SMDを選択する:

- 設計の柔軟性(形状、サイズ、特殊な配光)が必要だ。

- 用途は低~中電力(家庭用電球、ライトストリップ、装飾照明、バックライトなど)。

- コストを第一に考える(特に初期機器のコスト)。

- 修理が容易(個々のLEDを交換)。

- 最高の演色性は非常に要求される(一部のトップSMDはCRI>98に達する)。

いつCOBを選択するか:

- 高出力/高輝度出力が必要(工業用照明、街灯)。

- 光の均一性、柔らかさ、まぶしさの少なさが重要です(業務用スポットライト、ダウンライト、高品質の室内照明など)。

- 照明器具はスペースが限られており、高い光度を得るためには小さな発光面が必要である(懐中電灯やヘッドライトなど)。

- 照明器具の組み立てと製造工程を簡素化したい。

- 優れた熱管理性能は重要な要件である(COBは熱抵抗が低いという明確な利点がある)。

- 従来の光源(面発光特性)に近い視覚体験を追求。